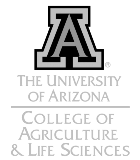

Earlier this year, we completed fabrication of a prototype commercial scale steam applicator for injecting steam into the soil prior to planting. The concept behind soil steaming is similar to soil solarization - heat the soil to levels sufficient to kill soilborne pathogens and weed seeds (typically 140 °F for >20 minutes). The self-propelled machine is principally comprised of a 100 BHP steam generator mounted on tracks and a steam applicator sled (Fig. 1). Steam is applied via shank injection as the machine travels through the field. After cooling (< ½ a day), the crop is planted into the disinfested soil.

The device has been demonstrated in several on-farm, field-scale (>1-acre plots) tests in Salinas, CA this summer. Although the trials are still in progress, preliminary results indicate that the machine is performing well and similar to our previous steam applicator prototypes. In those trials, we found that soil steaming provided excellent weed control (>90%), suppressed problematic soilborne diseases (Fusarium wilt of lettuce >50%, lettuce drop >70%), reduced Pythium spp. counts in soil assays (>93%) and increased crop yields (>24%).

For this upcoming season, we are seeking collaborators to conduct similar field-scale on-farm demonstrations in Yuma, AZ. The primary objectives would be to assess the viability of soil steaming at the field-scale level and obtain grower feedback on the device’s commercial potential. The machine can be adjusted to work with most bed configurations including narrow (40”, 42”) and wide (80”, 84”) beds, and is suitable for use in conventional or organic crops (soil steaming is organically compliant). To date, the device has been successfully tested in iceberg lettuce, romaine lettuce, baby leaf spinach and carrot crops.

If you are interested in an on-farm demo of soil steaming, please let me know. We have resources to conduct 3-4 on-farm demos, so space is limited. I’d be happy to work with you.

Fig. 1. Self-propelled steam applicator principally comprising a a) 100 BHP steam

generator mounted on tracks and a b) steam applicator sled that applies steam via

c) shank injection as beds are formed.