I hope you are frolicking in the fields of wildflowers picking the prettiest bugs.

I was scheduled to interview for plant pathologist position at Yuma on October 18, 2019. Few weeks before that date, I emailed Dr. Palumbo asking about the agriculture system in Yuma and what will be expected of me. He sent me every information that one can think of, which at the time I thought oh how nice!

When I started the position here and saw how much he does and how much busy he stays, I was eternally grateful of the time he took to provide me all the information, especially to someone he did not know at all.

Fast forward to first month at my job someone told me that the community wants me to be the Palumbo of Plant Pathology and I remember thinking what a big thing to ask..

He was my next-door mentor, and I would stop by with questions all the time especially after passing of my predecessor Dr. Matheron. Dr. Palumbo was always there to answer any question, gave me that little boost I needed, a little courage to write that email I needed to write, a rigid answer to stand my ground if needed. And not to mention the plant diagnosis. When the submitted samples did not look like a pathogen, taking samples to his office where he would look for insects with his little handheld lenses was one of my favorite times.

I also got to work with him in couple of projects, and he would tell me “call me John”. Uhh no, that was never going to happen.. until my last interaction with him, I would fluster when I talked to him, I would get nervous to have one of my idols listening to ME? Most times, I would forget what I was going to ask but at the same time be incredibly flabbergasted by the fact that I get to work next to this legend of a man, and get his opinions about pest management. Though I really did not like giving talks after him, as honestly, I would have nothing to offer after he has talked. Every time he waved at me in a meeting, I would blush and keep smiling for minutes, and I always knew I will forever be a fangirl..

Until we meet again.

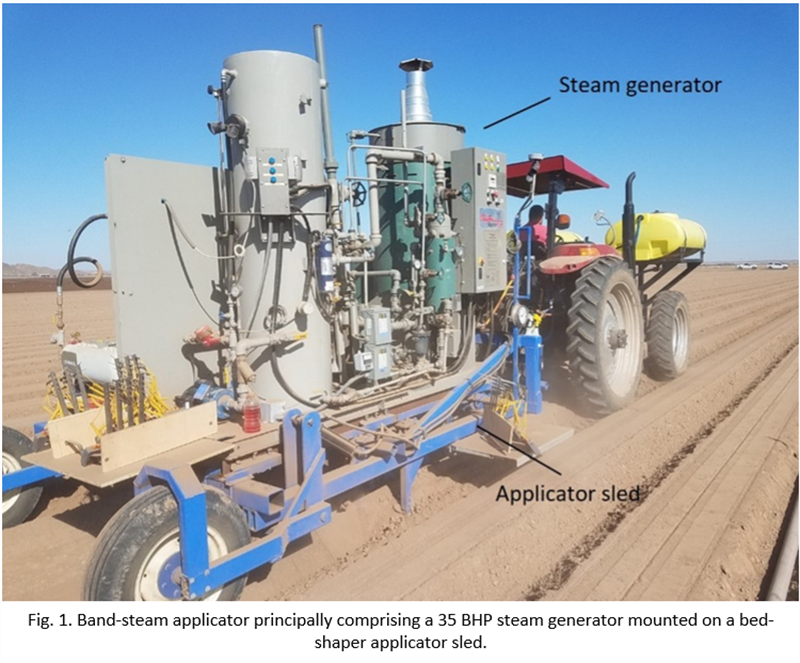

In previous articles (Vol. 11 (13), Vol. 11 (20), Vol. 11(24)), I’ve discussed using band-steam to control plant diseases and weeds. Band-steaming is where steam is used to heat narrow strips of soil to temperature levels sufficient to kill soilborne pathogens and weed seed (>140 °F for > 20 minutes). The concept is showing good promise. This past season, three trials were conducted examining the efficacy of using steam for disease and weed control in Yuma, AZ. In the studies, steam was applied in a 4-inch-wide by 2-inch-deep band of soil centered on the seedline using a prototype band-steam applicator (Fig.1). The band-steam applicator is principally comprised of a 35 BHP steam generator mounted on top of an elongated bed shaper. The apparatus applies steam via shank injection and from cone shaped ports on top of the bed shaper.

Trial results were very encouraging as the prototype applicator was able to raise soil temperatures to target levels (140°F for >20 minutes) at viable travels speeds of 0.75 mph. Steam provided better than 80% weed control and significantly lowered hand weeding time by more than 2 hours per acre (Table 1). Results also showed that Fusarium colony forming units (CFU) were reduced from 2,600 in the control to 155 in the 0.75 mph and 53 in the 0.5 mph treatments, respectively (a more than 15-fold reduction). A significant difference in Fusarium wilt of lettuce disease incidence was not found, however disease infection at the field site was low (< 2%) and differences were not expected. At 0.5 mph, fuel costs were calculated to be $238/acre which was considered reasonable and consistent with the values reported by Fennimore et al. (2014).

An unexpected finding was that plants in steam treated plots appeared to be healthier and more vigorous than untreated plots (Fig. 2). This trial is still in progress and it will be interesting to see if this improved early growth translates into increases in crop yield.

In summary, early trial results are showing good promise for use of band-steam as a non-herbicidal method of pest control. We plan on conducting further trials in this multi-year study. If you are interested in evaluating the device on your farm and being part of the study please contact me. We are particularly interested in fields with a known history of Fusarium wilt of lettuce and/or Sclerotinia lettuce drop that will be planted to iceberg or romaine lettuce.

As always, if you are interested in seeing the machine operate or would like more information, please feel free to contact me.

Acknowledgements

This work is supported by Crop Protection and Pest Management grant no. 2017-70006-27273/project accession no. 1014065 from the USDA National Institute of Food and Agriculture, the Arizona Specialty Crop Block Grant Program and the Arizona Iceberg Lettuce Research Council. We greatly appreciate their support. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.

A special thank you is extended to Mellon Farms for allowing us to conduct this research on their farm.

References

Fennimore, S.A., Martin, F.N., Miller, T.C., Broome, J.C., Dorn, N. and Greene, I. 2014. Evaluation of a mobile steam applicator for soil disinfestation in California strawberry. HortScience 49(12):1542-1549.

Click link below or picture to see the band-steam and co-product applicator in action!

Weeds are one of the most visible of all agricultural pests. They can’t move or hide and once established often stick up over the crop. Just one weed in a 10 acre field is annoying to look at. With insects and diseases, the damage is often more visible than the pest. That is not the case with weeds. A moderate weed infestation is approximately 10 weeds per square foot. If a herbicide produces 90% control, that leaves 1 weed per square foot or 43 weeds per acre. Without an untreated check, this can look like the herbicide failed! It is easy to leave an untreated spot in a field and it is well worth doing. Many applicators do so unintentionally because of skips, powerlines and other causes. They help determine crop injury and weed control. Here are some examples of what various levels of control looked like from one of our cole crop trials: