Soils with excess soluble salts, saline soils, and/or excess sodium (Na+) concentrations (sodic) are a natural feature of desert soils and common in arid land agriculture. This is primarily due to an accumulation of soluble salts near the soil surface as water evaporates from the soil surface.

Saline soils are a problem in crop production systems because of the sensitivity to salinity of crop plants, although plants vary in their degree of sensitivity. The period of greatest plant sensitivity to salinity is in the early stages of development, during germination and stand establishment.

Sodic soils are a problem in crop production systems because of the adverse effects of excess sodium on soil structure, causing a dispersion of soil particles and the breakdown of soil aggregates. This leads to poor water infiltration and percolation in the soil profile.

Some basic points associated with saline and/or sodic soils and management are outlined in the following sections.

https://www.nrcs.usda.gov/wps/PA_NRCSConsumption/download/?cid=nrcseprd589210&ext=pdf

Sodic soil reclamation does require an amendment that will facilitate the chemical exchange of Na+, usually from a calcium (Ca2+) source, such as gypsum (CaSO4).

An effective and straightforward method of calculating a leaching requirement (LR) can be calculated with the following equation that was presented by the USDA Salinity Laboratory (Ayers and Westcot, 1989).

Leaching Requirement (LR) Calculation:

Where:

ECw = salinity of the irrigation water, electrical conductivity (dS/m)

ECe = critical plant salinity tolerance, electrical conductivity (dS/m)

i.Drip irrigation systems are commonly very limited in this respect.

i.Examples: wheat, alfalfa, sudangrass, etc.

At the UC Cooperative Extension 2024 Automated Technology Field Day in Salinas, CA a couple of weeks ago, 12 of the latest automated and robotic technologies were demonstrated in the field. Most were designed for weed control or thinning vegetable crops. Several of the technologies shown are relatively “new” for the 2024 season. These included laser weeders that also are capable of thinning lettuce (Fig. 1 & 2), a smart cultivator/side-dresser that cultivates between individual crop plants and simultaneously applies fertilizer at a variable rate depending on plant size (Fig. 3), a spot sprayer that utilizes superheated vegetable oil to kill weeds (Fig. 4), and a self-propelled machine that disinfests soil prior to planting using steam. Although the test runs were short, I was impressed with the possibilities for these machines. Company representatives said they will be in Arizona this upcoming season and are interested in meeting with growers. Company contact information can be found at their respective websites, or feel free to contact me if you would like additional information.

Fig. 1. Carbon Robotics’1 (Seattle, WA) LaserWeederTM. The unit utilizes a vision

system to detect crop plants and weeds. A laser is used to kill unwanted plants.

The machine can be used for weeding or thinning lettuce crops (bottom).

Fig. 2. L&A1 (Chico, WA) autonomous laser weeding/thinning robot. The unit is

equipped with a vision system to detect crop plants and weeds, and a laser to kill

unwanted plants. The machine can be used for crop thinning or weeding (weeded

carrot crop, bottom).

Fig. 3. Stout Industrial Technology’s1 (Salinas, CA) smart cultivator/side

dresser. The unit is equipped with a vision system for detecting crop plants, and

blades that move in and out of the crop row to remove in-row weeds. Liquid

fertilizer (shown colored with blue dye) is applied at a variable rate depending on

plant size.

Fig. 4. Tensorfield Agriculture1 (Union City, CA) precision spot spray weeding

machine. The unit has an 80” wide spray boom equipped with 232 individually

controllable spray nozzles to spot spray weeds with superheated vegetable oil

(bottom left, bottom right). A vision system is used to detect weeds and spot

spray resolution is ¼”.

Fig. 5. UA/UC Davis self-propelled band-steam applicator. Device injects steam

into the soil to kill weed seed and soilborne pathogens prior to planting.

[1] Reference to a product or company is for specific information only and does not endorse or recommend that product or company to the exclusion of others that may be suitable.

The Southwest Agricultural Summit that recently took place in Yuma included a breakout session on Thursday, 21 February 2024 titled “New Developments in Weed Control”.

In this session Jose Antonio Cabrera representing BASF technical services for Coastal CA and Arizona provided a review of the new technologies being developed by his company in the Weed Control area. This includes new active ingredients as well as novel encapsulation technologies. The breakout session also included the lecture “Registration Support for Pest Management Tools in Specialty Crops, The IR-4 Project: Purpose and Process” by Roger B. Batts. “The IR-4 Project was established in 1963 by the U.S. Department of Agriculture to ensure that specialty crop farmers have legal access to safe and effective crop protection products. Helps growers address pest management concerns, develops data necessary for the registration of safe and effective pest management solutions with the U.S. Environmental Protection Agency1.

Roger is the Weed Science biologist from the NC State University IR-4 headquarters. If you have questions such as: What is the IR-4 Mission? Why is IR-4 Needed? What are the programs within the IR-4 project? you will find some answers in the IR-4 Presentation Slides here.

We are currently conducting trials in Yuma in coordination with this project that could result in the addition of new labels and weed control tools for our Arizona vegetable growers.

Thank you for attending the SW Ag Summit Weed Science breakout session.

Reference:

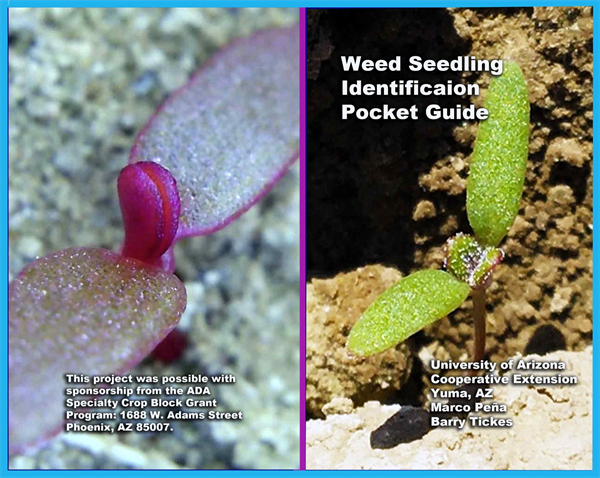

Get your free copy of the Weed Seedling Identification Pocket Guide at the Yuma

Agricultural Center.