Chile (Capsicum annuum) production is an important aspect of vegetable crop production systems in the desert Southwest. The Capsicum annuum species is the most common group of chiles that we encounter and these chiles are common in our southwestern diet. The New Mexico type chile (aka, Anaheim) is a common crop in the desert Southwest including southeastern Arizona, southern New Mexico, west Texas, and northern Chihuahua, Mexico.

There are five domesticated species of chile peppers. 1) Capsicum annuum is probably the most common to us and it includes many common varieties such as bell peppers, wax, cayenne, jalapeños, Thai peppers, chiltepin, and all forms of New Mexico chile. 2) Capsicum frutescens includes malagueta, tabasco, piri piri, and Malawian Kambuzi. 3)Capsicum chinense includes what many consider the hottest peppers such as the naga, habanero, Datil, and Scotch bonnet. 4) Capsicum pubescens includes the South American rocoto peppers. 5) Capsicum baccatum includes the South American aji peppers (Guzman and Bosland, 2017). Some examples are shown in Figure 1 and some other chile pepper species as well.

Figure 1. Capsicum annuum pod types include A) Asian, B) Cayenne, C) Chile de Arbol, D) Chiltepin, E) Hungarian Paprika, F) Jalapeño, G) New Mexican, and H) Poblano. A Capsicum baccatum pod type is I) Aji. Capsicum chinense pod types are J) Bhut Jolokia, K) Habanero, and L) Scorpion. A Capsicum pubescens

pod type is M) Rocoto and a Capsicum frutescens pod type is N)

Tabasco. Source: Guzman and Bosland, 2017.

Crop Phenology

Efficient management of a crop requires an understanding of the basic stages of plant growth in relation to time or age (crop phenology) and basic crop needs. There is a strong phenological relationship with morphological and physiological changes that are taking place and the input requirements important for the crop as the plant develops. As plants change physiologically and morphologically through their various stages of growth, water and nutritional requirements are great examples of crop demand changes that should influence management of the crop in the field.

Heat units (HUs) can be used as a measure of “thermal time” that drives plant development. Thus, HUs can be used as an important management tool for more efficient timing of irrigation and nutrient inputs to crop and pest management strategies. Plants will develop over a range of temperatures which is defined by the lower and upper temperature thresholds for growth (Figures 2 and 3).

Heat unit systems consider the elapsed time that local temperatures fall within the set upper and lower temperature thresholds and thereby provide an estimate of the expected rate of development for the crop. Heat unit systems have largely replaced days after planting in crop phenology models because they consider day-to-day fluctuations in temperature. People still use days after planting to estimate stages of crop development but HUs are more accurate and reliable.

Crop phenology models describe how crop growth and development are impacted by weather and climate and provide an effective way to standardize crop growth and development among different years and across many locations (Baskerville and Emin, 1969; Brown, 1989).

The use of HU-based phenology models is particularly important and applicable in irrigated crop production systems where water is a non-limiting factor. Water stress will alter phenological plant development and it is a major source of variation in crop development models. Accordingly, irrigated systems are more consistent in crop development patterns and HU models can be much more consistent and reliable.

Chiles are a warm season, perennial plant with an indeterminant growth habit that we grow and manage as an annual crop. The fruiting cycle begins at the crown stage of growth and continues until the plant reaches a point of “cut-out” with a hiatus in blooming as the plant works to mature the chile fruit crop that has been developed.

Figure 4 describes the basic phenological baseline for New Mexico – type chile and was developed from field studies conducted in New Mexico and Arizona (Silvertooth et al., 2010 and 2011; Soto et al., 2006; and Soto and Silvertooth, 2007). The use of HUs (86/55 oF thresholds) are applied in this development model since chiles are a warm season plant (Figures 2 and 3).

Heat units accumulated after planting (HUAP) for any date of planting to the present date can be easily accessed in the Arizona Meteorological Network (AZMET) website.

https://azmet.arizona.edu/

Also, the new HUAP tool for cotton that Dr. Jeremy Weiss, AZMET Director, recently developed can be used for chiles or other warm season crops. The same 86/55 oF thresholds are used and the model does not know what crop you are working with. It is a quick and easy way to calculate HUAP totals for any planting date in 2024.

https://viz.datascience.arizona.edu/azmet/cotton-growth-stages-and-heat-units/

Figure 2. Typical relationship between the rate of plant growth and development

and temperature. Growth and development ceases when temperatures decline

below the lower temperature threshold (A) or increase above the upper

temperature threshold (C). Growth and development increases rapidly when

temperatures fall between the lower and upper temperature thresholds (B).

Figure 3. Heat unit calculation with the sine curve method using upper and

lower temperature thresholds (Brown, 1989). The 86/55 ºF thresholds are used,

consistent with most warm season crops.

Figure 4. Basic phenological guideline for irrigated New Mexico-type chiles.

References

Baskerville, G.L. and P. Emin. 1969. Rapid estimation of heat accumulation from maximum and minimum temperatures. Ecology 50:514-517.

Bosland, P.W., E.J. Votava, and E.M. Votava. 2012. Peppers: Vegetable and spice capsicums. Wallingford, U.K.: CAB Intl.

Brown, P. W. 1989. Heat units. Bull. 8915, Univ. of Arizona Cooperative Extension, College of Ag., Tucson, AZ.

Guzmán, I. and P.W. Bosland. 2017. Sensory properties of chile pepper heat - and its importance to food quality and cultural preference. Appetite, 2017 Oct 1;117:186-190. doi: 10.1016/j.appet.2017.06.026.

Silvertooth, J.C., P.W. Brown, and S. Walker. 2010. Crop Growth and Development for Irrigated Chile (Capsicum annuum). University of Arizona Cooperative Extension Bulletin No. AZ 1529

Silvertooth, J.C., P.W. Brown and S.Walker. 2011. Crop Growth and Development for Irrigated Chile (Capsicum annuum). New Mexico Chile Association, Report 32. New Mexico State University, College of Agriculture, Consumer and Environmental Science.

Soto-Ortiz, Roberto, J.C. Silvertooth, and A. Galadima. 2006. Crop Phenology for Irrigated Chiles (Capsicum annuum L.) in Arizona and New Mexico. Vegetable Report, College of Agriculture and Life Sciences Report Series P-144, November, University of Arizona.

Soto-Ortiz, R. and J.C. Silvertooth. 2007. A Crop Phenology Model for Irrigated New Mexico Chile (Capsicum annuum L.) The 2007 Vegetable Report. Jan 08:104-122.

I hope you are frolicking in the fields of wildflowers picking the prettiest bugs.

I was scheduled to interview for plant pathologist position at Yuma on October 18, 2019. Few weeks before that date, I emailed Dr. Palumbo asking about the agriculture system in Yuma and what will be expected of me. He sent me every information that one can think of, which at the time I thought oh how nice!

When I started the position here and saw how much he does and how much busy he stays, I was eternally grateful of the time he took to provide me all the information, especially to someone he did not know at all.

Fast forward to first month at my job someone told me that the community wants me to be the Palumbo of Plant Pathology and I remember thinking what a big thing to ask..

He was my next-door mentor, and I would stop by with questions all the time especially after passing of my predecessor Dr. Matheron. Dr. Palumbo was always there to answer any question, gave me that little boost I needed, a little courage to write that email I needed to write, a rigid answer to stand my ground if needed. And not to mention the plant diagnosis. When the submitted samples did not look like a pathogen, taking samples to his office where he would look for insects with his little handheld lenses was one of my favorite times.

I also got to work with him in couple of projects, and he would tell me “call me John”. Uhh no, that was never going to happen.. until my last interaction with him, I would fluster when I talked to him, I would get nervous to have one of my idols listening to ME? Most times, I would forget what I was going to ask but at the same time be incredibly flabbergasted by the fact that I get to work next to this legend of a man, and get his opinions about pest management. Though I really did not like giving talks after him, as honestly, I would have nothing to offer after he has talked. Every time he waved at me in a meeting, I would blush and keep smiling for minutes, and I always knew I will forever be a fangirl..

Until we meet again.

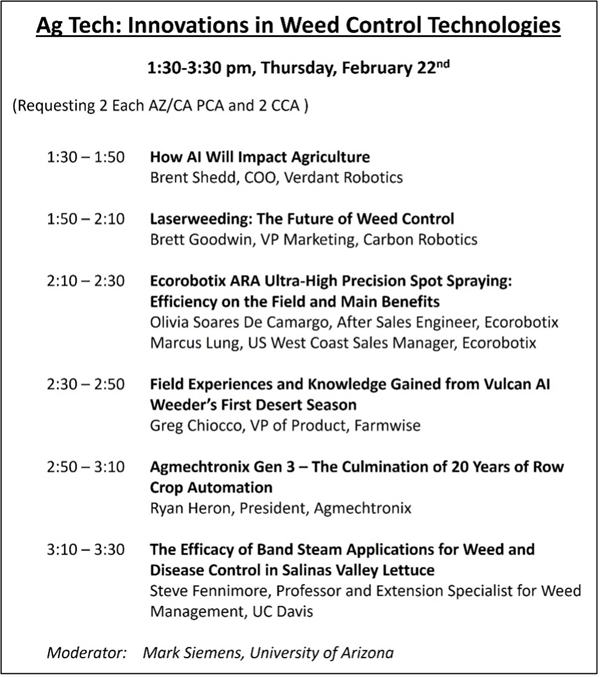

Keeping up to date with the latest developments in automated weeding machines is challenging. It’s a very fast-moving space with significant private and public investment. At the 2024 Southwest Ag Summit “Ag Tech: Innovations in Weed Control Technologies” breakout session, university experts and cutting-edge innovators will provide updates on laser weeding, high precision smart spot sprayers, robotic/automated weeders and band steam (agenda below).The session will be held TOMMOROW Thursday, February 22nd from 1:30-3:30 pm at Arizona Western College in Yuma, AZ.

As I mentioned in the last newsletter, there will also be a Field Demo where several of these technologies and other state-of-the-art automated weeders will be demonstrated operating in the field. The Field Demo is scheduled for TODAY, Wednesday, February 21st. Breakfast will be served at 7:00 am and demonstrations begin at 8:00 am. The event will also be held at AWC.

We will also have our 3rd generation prototype steam soil disinfestation machine on display at the event (Fig. 3). It is a self-propelled machine designed for commercial field scale operations. The device injects steam into the soil prior to planting to raise soil temperatures to levels sufficient to kill soilborne pathogens and weed seed (typically 140 °F > 20 minutes). We have had very good results with our previous prototypes and would like to demonstrate soil steaming to interested growers next season with the new machine. In addition to obtaining grower feedback on the viability of soil steaming, a second objective is to validate our small plot research results at the field scale level. If you are interested in the technique and would like a demo on your farm, please let me know. I would be happy to collaborate with you.

For more information about the Southwest Ag Summit, visit https://yumafreshveg.com/southwest-ag-summit/.

Fig. 1. Agenda for the “Ag Tech: Innovations in Weed Control Technologies”

educational session at the 2024 Southwest Ag Summit. The session will be held

Thursday, February 22nd at Arizona Western College, Yuma, AZ.

Fig. 2. 2024 Southwest Ag Summit Field Demo agenda. The event will

be held at Arizona Western College in Yuma, AZ.

Fig. 3. Self-propelled machine designed for injecting steam into the

soil prior to planting to raise soil temperatures to sufficient levels to

control soilborne pathogens and weed seed. Unit will be on display at

the 2024 Southwest Ag Summit, Yuma, AZ. (Photo credit: Peter de

Groot).

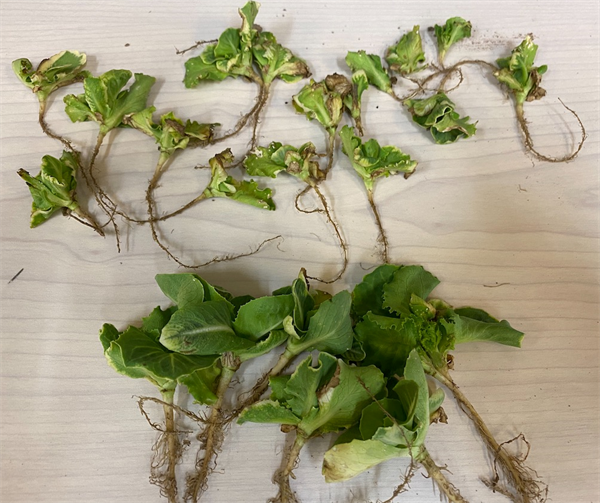

During this time of the year, we visit fields and constantly receive plant samples with symptoms of what could be herbicide, disease, or insect injury. Our Plant Pathologist Dr. Bindu Poudel-Ward analyzes them for pathogens, Dr. John Palumbo checks for insect damage, and we also examine for possible herbicide injury.

As we all know IPM involves an interdisciplinary effort to identify and prevent problems we encounter in our industry.

Kerb, Balan, and Prefar are the major herbicides we have used in lettuce production in Arizona for the last 50 years. These herbicides work by inhibiting root growth in small weeds and under some specific conditions can injure lettuce.

Symptoms of injury could include stunting, leaf margin chlorosis, malformation of the cotyledons and first true leaves, inhibition of main root and lateral roots. Diagnostics sometimes can be challenging because some of the symptoms can also be produced by other factors such as the soil salinity, water management problems, environmental stress or cold, diseases, possible drift from chemical thinning operations and other factors.

It is common that growers send soil or tissue samples to laboratories to compare herbicide concentrations from a healthy section of the field with the affected injured area. If the concentration of the compound in question is significantly different between “healthy” and “bad” samples this could be an indication of herbicide injury. Most laboratories use gas chromatographs (GC) and liquid chromatographs (HPLC) for analysis. Standard extraction and detection methods are costly but accurate and precise3.

The following links will take you to publications that (1) could help you identify some of the symptoms of common lettuce herbicide injury and (2) interpret results reported by laboratories.

References: