Springtime in the desert serves host to a new spring melon/cantaloupe crop. That is particularly true in the lower Colorado River valleys. Cantaloupes (Cucumis melo ‘reticulatus’ L.) or “melons” are one of the important spring and fall vegetable crops of Arizona and the desert Southwest.

Technically, “true” cantaloupes (Cucumis melo ‘cantaloupensis’) are rough, warty fruit, primarily grown in Europe. On a production scale, cantaloupes are not grown commercially in the United States. However, in the United States “cantaloupe” has become a general name of all netted, musk-scented melons (Simonne et al., 1998 and Soto, 2012).

Being able to accurately describe and predict important stages of crop growth and development (crop phenology) and harvest dates is important for improving melon crop management (e.g. fertilization, irrigation, harvest scheduling, pest management activities, labor, and machinery management, etc.). Since plants operate on “thermal time”, they have no regard for calendars or time as we commonly measure it. So, it is best to monitor and predict plant development based on the actual thermal conditions in the plant’s environment.

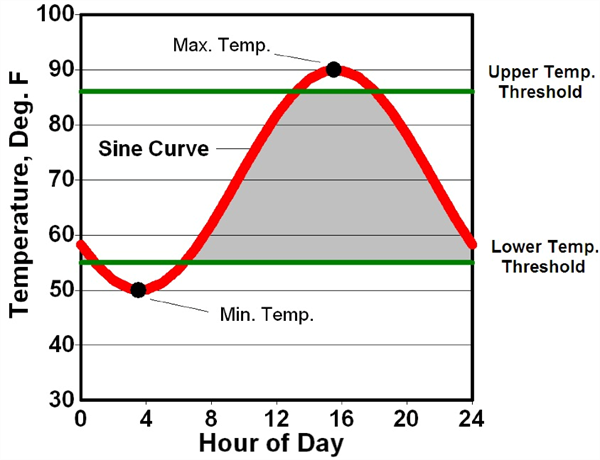

Various forms of temperature measurements and units commonly referred to as heat units (HU), growing degree units (GDU), or growing degree days (GDD) have been utilized in numerous studies to predict phenological events for many crop plants (Baskerville and Emin, 1969; Brown, 1989; Baker and Reddy, 2001; and Soto, 2012). A graphical depiction of HU computation using the single sine curve procedure is presented in Figure 1 (Brown, 1989).

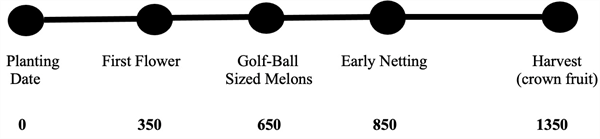

Since 2000, we have been working on the development and annual testing of a phenology model for desert cantaloupe production for Arizona conditions. The basic cantaloupe phenology model is shown in Figure 2 (Silvertooth, 2003; Soto et al., 2006; and Soto, 2012). This melon crop phenology model was developed under fully irrigated conditions.

Guideposts indicated in Figure 2 represent general average or “target” values and a slight degree of variation is normal. It is important to note that water or nitrogen stress are two factors that will significantly alter physiological development of a crop.

Referencing the data from the Arizona Meteorological Network (AZMET) and several locations in the Yuma area, the HU accumulations (86/55 ºF thresholds) from a range of possible 2024 melon planting dates to 28 April are listed in Table 1. These HU accumulations can be referenced against the melon phenology model in Figure 2 and crop conditions in the field.

I encourage those who are working with spring cantaloupe production this season to test and evaluate this crop phenology model in the field under various planting dates, varieties, and conditions. The information in Table 1 can help serve as a reference to check melon crop development in the field against this phenological model. We appreciate your feedback.

References:

Baker, J.T., and V.R. Reddy. 2001. Temperature effects on phenological development and yield of muskmelon. Annals of Botany. 87:605-613.

Baskerville, G.L., and P. Emin. 1969. Rapid estimation of heat accumulation from maximum and minimum temperatures. Ecology 50:514-517.

Brown, P. W. 1989. Heat units. Ariz. Coop. Ext. Bull. 8915. Univ. of Arizona, Tucson, AZ.

Silvertooth, J.C. 2003. Nutrient uptake in irrigated cantaloupes. Annual meeting, ASA-CSSA-SSSA, Denver, CO.

Simonne, A., E. Simonne, R. Boozer, and J. Pitts. 1998. A matter of taste: Consumer preferences studies identify favorite small melon varieties. Highlights of Agricultural Research. 45(2):7-9.

Soto, R. O. 2012. Crop phenology and dry matter accumulation and portioning for irrigated spring cantaloupes in the desert Southwest. Ph.D. Dissertation, Department of Soil, Water and Environmental Science, University of Arizona.

Soto-Ortiz, R., J.C. Silvertooth, and A. Galadima. 2006. Nutrient uptake patterns in irrigated melons (Cucumis melo L.). Annual Meetings, ASA-CSSA-SSSA, Indianapolis, IN.

|

Location |

15 January |

1 February |

15 February |

1 March |

|

Yuma Valley |

994 |

893 |

832 |

680 |

|

Yuma N. Gila |

972 |

856 |

797 |

650 |

|

Yuma South |

961 |

862 |

802 |

655 |

Table 1. Heat unit accumulations (86/55 ºF thresholds) from four possible 2024 planting dates utilizing Arizona Meteorological Network (AZMET) data for each representative site.

Yuma Valley:https://ag.arizona.edu/azmet/02.htm

Yuma South: https://ag.arizona.edu/azmet/36.htm

Yuma North Gila: https://ag.arizona.edu/azmet/14.htm

Figure 1. Graphical depiction of heat unit computation using the single sine

curve procedure. A sine curve is fit through the daily maximum and minimum

temperatures to recreate the daily temperature cycle. The upper and lower

temperature thresholds for growth and development are then superimposed

on the figure. Mathematical integration is then used to measure the area

bounded by the sine cure and the two temperature thresholds (grey area).

(Brown, 1989)

Figure 2. Heat Units Accumulated After Planting (HUAP, 86/55 oF)

I hope you are frolicking in the fields of wildflowers picking the prettiest bugs.

I was scheduled to interview for plant pathologist position at Yuma on October 18, 2019. Few weeks before that date, I emailed Dr. Palumbo asking about the agriculture system in Yuma and what will be expected of me. He sent me every information that one can think of, which at the time I thought oh how nice!

When I started the position here and saw how much he does and how much busy he stays, I was eternally grateful of the time he took to provide me all the information, especially to someone he did not know at all.

Fast forward to first month at my job someone told me that the community wants me to be the Palumbo of Plant Pathology and I remember thinking what a big thing to ask..

He was my next-door mentor, and I would stop by with questions all the time especially after passing of my predecessor Dr. Matheron. Dr. Palumbo was always there to answer any question, gave me that little boost I needed, a little courage to write that email I needed to write, a rigid answer to stand my ground if needed. And not to mention the plant diagnosis. When the submitted samples did not look like a pathogen, taking samples to his office where he would look for insects with his little handheld lenses was one of my favorite times.

I also got to work with him in couple of projects, and he would tell me “call me John”. Uhh no, that was never going to happen.. until my last interaction with him, I would fluster when I talked to him, I would get nervous to have one of my idols listening to ME? Most times, I would forget what I was going to ask but at the same time be incredibly flabbergasted by the fact that I get to work next to this legend of a man, and get his opinions about pest management. Though I really did not like giving talks after him, as honestly, I would have nothing to offer after he has talked. Every time he waved at me in a meeting, I would blush and keep smiling for minutes, and I always knew I will forever be a fangirl..

Until we meet again.

A couple years ago, we conducted evaluations of various “new” technologies for cultivating weeds in cotton as compared to conventional methods. The new technologies included 1) a camera-guided side-shift hitch and 2) finger weeders, an in-row weeding tool (Fig. 1). Camera-guidance of the maneuverable hitch allows cultivating tools to be positioned close to the seed row. In the study, the uncultivated band was 3.5" for the camera-guided system, and 6” for the conventional cultivator. The aim of evaluating these technologies was to determine their efficacy in controlling herbicide resistant weeds. Trials conducted over 3 years showed that use of camera-guidance improved weed control by more than 30% and finger weeders removed about 45% of the in-row weeds. Overall weed control using the two technologies together was roughly > 90% for broadleaf weeds and about 85% for all weeds species.

Studies conducted by Texas A&M over two years showed similar results (Dotray et. al, 2021).

It is logical to think that similar type results would be realized in vegetable crops such as broccoli and cauliflower, plants that also have fairly long plant stems at the seedling stage of growth. A better than 40% reduction of in-row weeds would significantly lower hand weeding requirements. If you are interested in trying these technologies in vegetable or other crops on your farm, please contact me. We still have the equipment and I’d be happy to work with you.

A presentation given on the trial results and videos of the equipment used operating can be found by clicking here or on image below.

References

Dotray, P.A., Keeling, J.W., & Russell, K.R. 2021. Precision cultivation with finger weeder systems. Project No. 20-190 Final Report. Cary, N.C: Cotton Inc.

Acknowledgements

Project partially funded and supported by Arizona Cotton Growers Association, Cotton Inc., KULT-Kress, LLC and Keithly-Williams Fabrication. We thank them for their support.

Fig. 1. Technologies for precision cultivation and in-row weeding used in

efficacy trials included a a) a camera-guided side-shift hitch attached to a

cultivator and b) in-row weeding tools (finger weeders).

Fig. 2. Click on image above to watch presentation on precision cultivation and

in-row weeding technologies.

Postemergence herbicides used for grass control in vegetables include Poast (sethoxydim), Select (clethodim) and Fusilade (fluazifop) and the generics of these active ingredients. When some grasses have escape or have survived the application of Pefar, Kerb and Balan these selective grass herbicides can come to the rescue and have shown to be a great tool for weed management.

The above-mentioned herbicides are all Acetyl CoA carboxylase or ACCase inhibitors. These products work slowly and even slower at lower temperatures and shorter days. Treated grasses should stop growing immediately and will slowly turn yellow, red and gradually die as the crop grows. The process takes about 15-21days. Select (clethodim) works the faster than Poast (sethoxydim), and it isrecommended to add a crop oil concentrate for better activity with the exception of Select Max which can be used either with crop oil concentrate or non-ionic surfactant.

References: