The continuous development, testing, and incorporation of technology in agriculture is amazing. I recently attended a western agricultural conference and when visiting the industry displays and booths, I was impressed with the new technologies that are coming into the agricultural arena.

Technological devices are tools and like all other tools, they are put to their best use in the hands of skilled craftsmen.

We have many excellent examples of technological tools in the crop production systems of the desert Southwest. A basic example comes from the equipment used to till the fields, prepare a good seedbed, and then to plant a new crop by seed or transplant. Excellent articles are provided in this newsletter on this topic regularly. We tend to take this kind of equipment for granted until you must do the job by hand or with older technology.

Any new technology needs to be fully tested and demonstrated before anyone can expect it to be appropriately implemented. That involves communicating the background, purpose, and utility of any new technology. The cost/benefit ratios need to be worked out and presented. A critical step in implementation is demonstration and establishing prima facie evidence to support the value of the new technology. Testimonials are nice but there needs to be solid evidence to support claims of merit. In science ideas demand testing and the presentation of proof.

A lot of emphasis recently has been placed on the technology and new tools available for soil-plant-water management and irrigation management. There is a tendency for some people to think that our problems can all be solved with crop water management if we would just use the right technology. In my view, some of the new irrigation technology is great and it can potentially be very useful in managing crop irrigation in the field. But technology itself is not a panacea.

Despite the technological advancements that we do use and benefit from, the best potential improvements are dependent upon the skill and expertise of the farmers or field managers involved. The skill set required to plant a crop, get a good stand, manage it to the proper level of maturity, harvest the crop, and then get it to market is indispensable and the responsibility comes down to individual farmers and farmer managers.

The successful management of irrigation technology is totally dependent on the skill of the operator to make a personal assessment of a broad array of factors. These factors include a review and assessment of the field in terms of crop condition and stage of growth, the soil moisture levels in relation to field capacity of the soil, the crop-specific irrigation requirements, allocating the appropriate amount of irrigation water needed, and the optimum time of application.

The ability of the farmer and/or farm manager to evaluate soils in the field regarding texture, water holding capacity, and current soil-water levels is essential. Simple methods such as using a soil probe and estimating soil-water levels by feel with their hands remains and will continue to be a critical skill for farmers and field managers.

I believe this is particularly true if one is trying to employ new technologies for irrigation management. A good farmer can tell if the tools and technologies being employed are working properly. They are the ones that usually take new tools to levels of use above and beyond what the developers were able to envision.

We all need a baseline in relation to crop-water management and the fundamentals will continue to be an important part of a farm manager’s skill set. The new technologies may serve as good tools, but they will not replace the capacity of a farm manager to go into the field and figure out what is going on, put the tools or technologies to work appropriately, and not only apply them but do it well.

Fundamentals are important, and they always will be. This illustrates the fact that skilled professionals are essential in crop production.

I hope you are frolicking in the fields of wildflowers picking the prettiest bugs.

I was scheduled to interview for plant pathologist position at Yuma on October 18, 2019. Few weeks before that date, I emailed Dr. Palumbo asking about the agriculture system in Yuma and what will be expected of me. He sent me every information that one can think of, which at the time I thought oh how nice!

When I started the position here and saw how much he does and how much busy he stays, I was eternally grateful of the time he took to provide me all the information, especially to someone he did not know at all.

Fast forward to first month at my job someone told me that the community wants me to be the Palumbo of Plant Pathology and I remember thinking what a big thing to ask..

He was my next-door mentor, and I would stop by with questions all the time especially after passing of my predecessor Dr. Matheron. Dr. Palumbo was always there to answer any question, gave me that little boost I needed, a little courage to write that email I needed to write, a rigid answer to stand my ground if needed. And not to mention the plant diagnosis. When the submitted samples did not look like a pathogen, taking samples to his office where he would look for insects with his little handheld lenses was one of my favorite times.

I also got to work with him in couple of projects, and he would tell me “call me John”. Uhh no, that was never going to happen.. until my last interaction with him, I would fluster when I talked to him, I would get nervous to have one of my idols listening to ME? Most times, I would forget what I was going to ask but at the same time be incredibly flabbergasted by the fact that I get to work next to this legend of a man, and get his opinions about pest management. Though I really did not like giving talks after him, as honestly, I would have nothing to offer after he has talked. Every time he waved at me in a meeting, I would blush and keep smiling for minutes, and I always knew I will forever be a fangirl..

Until we meet again.

Last week, we initiated our first trial of the season examining the use of band steam for controlling Fusarium wilt of lettuce. The premise behind this research is to use steam heat to raise soil temperatures to levels sufficient to kill soilborne pathogens. For Fusarium oxysporum f. sp. lactucae (FOL) the pathogen which causes Fusarium wilt of lettuce, the required temperature for control is generally taken to be > 140°F for 20 minutes. Soil solarization, where clear plastic is placed over the crop bed during the summer, exploits this concept. The technique raises soil surface temperatures to 150-155˚F, effectively killing the pathogen and reducing FOL disease incidence by 45-98% (Matheron and Porchas, 2010).

In our trials, we are using steam heat to raise soil temperatures. Steam is delivered by a 35 BHP steam generator mounted on a custom designed elongated bed shaper (Fig. 1). As the device travels through the field, steam is injected into the soil in narrow bands centered on the seedline. Soil temperatures are raised to about 190°F. After cooling (< ½ a day), the crop is planted into the disinfested soil.

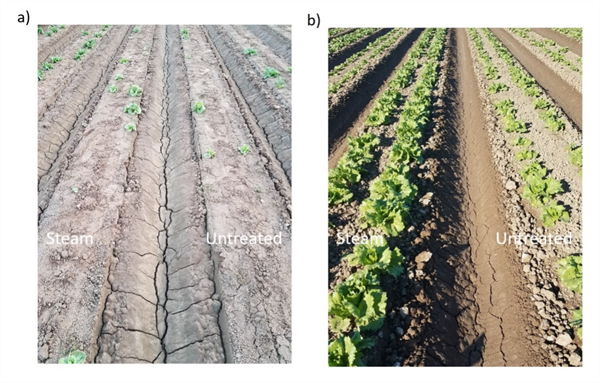

Trials conducted in prior years show the technique holds promise; however further work is needed. In these studies, a 4” wide by 2” deep band of soil was treated. Although soil assay results showed that steam treatment significantly reduced the number of Fusarium colony forming units by over 95% as compared to the untreated control, this didn’t always translate into reductions in disease incidence. At one field site with a known history of FOL, band-steam provided no benefit with virtually all lettuce plants succumbing to the disease (Fig 2a). However, at another site, disease incidence was reduced by more than 40%, plants appeared to be healthier and more vigorous, and yield was increased by more than 90% (Fig. 2b). One explanation for this difference is that at the first site, Fusarium inoculum loads were very high and the width and/or depth of soil treated by steam wasn’t large enough to protect seedling roots, which are highly susceptible to FOL, from infection. The aim of this year’s trial is to determine the width and depth of soil that needs to be disinfested to prevent disease. In the current study, we are examining bands of soil receiving steam treatment that range in size from 4” wide by 2” deep to 6” wide by 4” deep.

Stay tuned for final trial results and reports of our other studies examining the efficacy of using steam heat to control sclerotinia lettuce drop, pythium and weeds.

As always, if you are interested in trying band-steam on your farm or would like more information, please feel free to contact me.

References

Matheron, M. E., & Porchas, M. 2010. Evaluation of soil solarization and flooding as management tools for Fusarium wilt of lettuce. Plant Dis. 94:1323-1328.

Acknowledgements

This project is sponsored by USDA-NIFA, the Arizona Specialty Crop Block Grant Program and the Arizona Iceberg Lettuce Research Council. We greatly appreciate their support.

A special thank you is extended to Fatima Corona, Roberto Delgado, Chad VanMatre, Matt McGuire and JV Farms for their generous assistance and allowing us to conduct this research on their farm.

Fig. 1. Band-steam applicator principally comprising a 35 BHP steam generator

mounted on a bed-shaper applicator sled. The device injects steam into the soil

as beds are formed.

Fig. 2. Lettuce seedlings at field sites with (a) very high and (b)

moderate levels of Fusarium wilt of lettuce inoculum. Band-steam

(left) and untreated (right) plots are shown.

Teff grass (Eragrostis tef) is originally from Ethiopia and has gained a lot of interest in Arizona. This crop is planted between vegetables and grows under different conditions and soil types. It is a fast-growing crop and can be harvested multiple times. According to the Teff Grass Crop Overview and Forage Production Guide from 2007-09 in California it was cut an average of 4 times yielding 6.89 tons/acre. The palatability to livestock is good and some report that its preferred over other traditional grass hays1.

There is also a need for good weed control in Teff grass to satisfy buyers.

One herbicide that was tested for postemergence broadleaf weed control and crop safety is Simplicity (pyroxulam). A 24(c) Special Local Need Registration was extended for this product. Also, another product that is successfully used in our area for broadleaf weed control is Clarity (dicamba).

Teff is grown during the summer between other crops that could be susceptible to residue of herbicides, and it is important that any herbicide that is used doesn’t have long-term soil activity.

We conducted a trial last summer in the Yuma Valley to evaluate the crop safety of pyroxulam, dicamba and other herbicides. Our results for pyroxulam were consistent with the injury observed in the visual ratings obtained by B.J. Hinds-Cook, D.W. Curtis, A.G. Hulting and C.A. Mallory-Smith with a 10% recorded2.

Also, efficacy for the control Purslane (Portulaca oleracea) was evaluated. The following chart shows data obtained.