Jun 28, 2023

Controlling Weeds in Spinach Using Soil Applied Steam – Trial Results

Last month, we investigated the use of applying steam to the soil to control weeds in baby leaf spinach. In the study, we utilized the prototype steam applicator described in previous UA Veg IPM articles to inject steam into the soil prior to planting. The concept is to heat the soil to levels sufficient to kill soilborne pathogens and weed seeds (140 °F > 20 minutes). The device is principally comprised of a 63 BHP steam generator mounted on an elongated bed shaper (Fig. 1a). The apparatus applies steam via shank injection and from rectangular ports on top of the bed shaper. After cooling (< ½ a day), the crop is planted into the disinfested soil.

In the trial, the unit’s bed shaper (84” wide) was outfitted with twenty-four steam injection shanks positioned to inject steam into the soil at a depth of about 2” (Fig. 1b,1c). Six injectors were in a rank towards the front of the bed shaper with each injector spaced about 10.4” apart. Three additional ranks of 6 injectors, also with 10.4” injector spacing, were positioned behind the first rank. Ranks of injectors were offset such that the spacing between injectors across the frontal cross-section of the bed shaper was 2.6”. Travel speed was 0.20 mph.

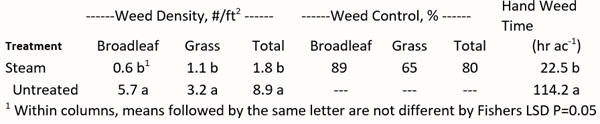

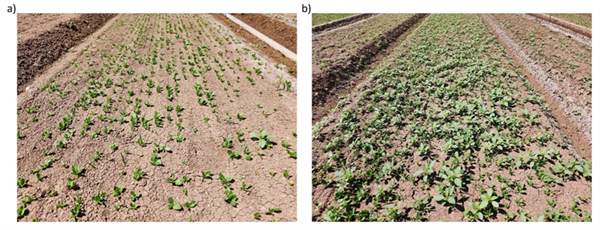

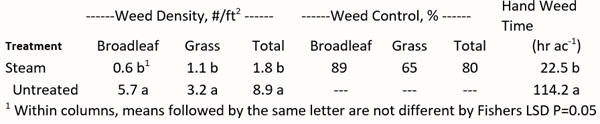

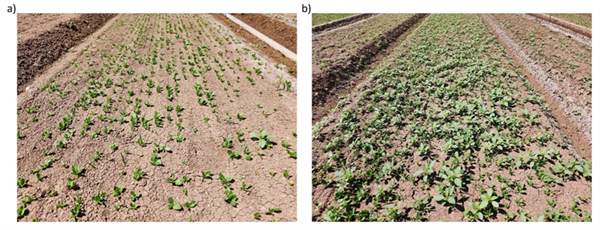

Results showed that steam treatment provided very good control of broadleaf weeds (89%) and moderate control of grassy weeds (65%) (Table 1, Fig. 3). Combined, overall weed control was 80%. The predominant species at the site were nettleleaf goosefoot, thumble pigweed, ground cherry, common purslane and junglerice. Although weed densities were still high in the steam treated plots (1.8 weeds/ft2), hand weeding times were reduced by a factor of 5 as compared to the untreated control.

Work rates and fuel costs were considered marginally acceptable at 0.14 ac/hr and $597/ac, respectively. However, it is estimated that travel speed can be increased by 50% by operating the device when initial soil temperatures are high (>130 °F) as compared to this study where soil temperatures were moderate (110 °F) since much less heat energy is needed to raise soil temperatures to target levels. If a 50% increase in travel speed were realized, work rate would be improved to 0.20 ac/hr (5 hr/ac) and fuel costs would be about $400/ac. These values are very reasonable and show good potential for use of the technique in spinach or spring mix crops where costs for hand weeding are very high. Later this summer, we plan to conduct trials in high temperature soils to determine the maximum travel speeds that can be utilized for effective weed control using steam.

If you are interested in soil steaming and would like a demo or to evaluate the machine on your farm, please let me know. I would be happy to collaborate with you.

Acknowledgements

This work is supported by the Arizona Specialty Crop Block Grant Program and the Crop Production and Pest Management grant no. 2021-70006-35761 /project accession no. 1027435 from USDA-NIFA. We appreciate their support. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.

Fig. 1. a) Band-steam applicator principally comprising a 63 BHP steam generator

mounted on a bed-shaper applicator sled. Steam applicator sled b) top view and

c) bottom view.

Table 1. Weed density and control of weeds with soil applied steam in baby leaf spinach trial.

Fig. 3. Weed control with steam in spinach. Steam was applied to the soil at a 2”

depth via shank injection prior to planting (a) and untreated control (b).

To contact Mark C. Siemens go to:

siemens@cals.arizona.edu