Crops need to be monitored during all stages of growth to best manage water and nutrient inputs. Taking crop condition into account and adjusting nutrient and water management accordingly is critical in achieving the optimum management of a crop and the best use of an irrigation system and fertilization program. This is often referred to as a “feedback” system of crop management (Silvertooth, 2001). This concept and approach to crop management can perhaps be most useful with an irrigated crop production system. Irrigated chile (Capsicum annuum L.) production in the desert Southwest is a good example and it demonstrates the benefits in crop management when coupled with a fundamental understanding of crop phenology (growth and development).

Increased efficiency is an important objective for developing sustainable chile crop production systems. Efficiency can be defined in economic (return on the investment), agronomic (crop system response), or environmental (impact on environmental quality) terms. Each of these concepts of efficiency can be successfully addressed simultaneously, which requires good management and attention to the changes that take place over the growth cycle of a crop.

When monitoring any crop in a production system there are several factors that are very important to consider including: 1) stage of growth, 2) crop vigor, and 3) yield potential. A feedback system of management can be useful in adjusting critical crop inputs such as water and fertilizer inputs (particularly N) in response to actual crop conditions. For example, in the case of irrigated chile, if the crop is experiencing poor vigor and symptoms of stress, it would be very important to identify the source of the stress and make an effort to address or correct it. This could relate to several issues such as pest infestations (insects, weeds, or diseases), water stress, salinity stress, nutrient deficiency, etc. If for example a crop is experiencing poor vigor due to water stress, the application of additional N will not be effectively utilized by the crop until the water stress situation is adequately addressed. Alternatively, if a chile crop is experiencing very high vigor and excessive vegetative growth (often accompanied by a poor fruit load), a more conservative approach with N inputs would be warranted and at the same time it would be important not to impose a water stress per se.

Thus, monitoring a chile crop production system and having a gauge on basic factors such as stage of growth and the plant relationships to water and nutrient requirements are essential in realizing optimum efficiency regarding irrigation and fertilization inputs. Flexibility in management is required to better respond to the crop and production conditions that can change quite rapidly during a production season and will vary from season to season. Accordingly, managers need to be flexible in managing the system in response to the appropriate queues to realize the full potential from a crop production system. This type of agronomic system efficiency is important for both short- and long-term sustainability.

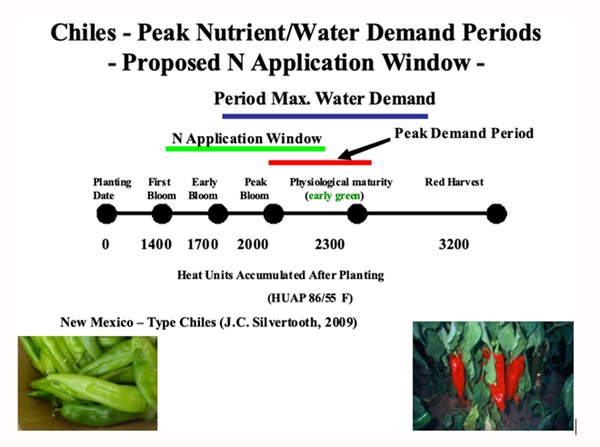

To optimize N management for a chile crop it is important to make fertilizer N applications in the “Nitrogen Application Window” (NAW) described in Figure 1 which provides a baseline for chile growth and development as a function of heat units accumulated after planting (HUAP, 86/55 F thresholds; Brown, 1989; Baskerville and Emin, 1969). Chile crop phenology as a function of HUAP is described in Extension Bulletin AZ1529 (Silvertooth et al., 2010). The NAW is positioned just prior to the period peak N demand by the chile crop during the phase of growth when N demand is rapidly increasing after the crowning stage of development. Nitrogen applications made in this manner in advance of the N demand period increases the probability of fertilizer N uptake and recovery by the plant. Thus, the NAW extends from the crowning stage to just past peak bloom (~1200 – 2300 HUAP).

Chile crop water demand also increases quite rapidly during this same period of growth with maximum chile crop water demand occurring from early bloom until the completion of development of the primary pod set (~1600 – 2500 HUAP). For green chile this peak water demand will extend up to the time of crop harvest. For red chile, peak water demand declines as the crop transitions from ~ 50% green and 50% red chile on the plants, or the stage that is commonly referred to as the maximum “chocolate chile” stage.

For both water and N management it is important to monitor crop growth and development as well crop condition including vigor, fruit load, etc. Water stress should be avoided during these stages of growth and N management needs to be flexible in response to changes in crop condition during these peak periods of demand. Crop monitoring and flexibility are key elements to management for optimum crop production efficiency.

Nitrogen application rates will vary depending on other factors such as residual soil N levels, N concentrations in the irrigation water, previous N fertilizer applications, cropping history for the field and residual crop residues, as well as the current condition of the crop or field in question. Nutrient uptake studies have shown that approximately 180 lbs. N/acre is the maximum amount of total N required by green and red chile crops for optimum yields. Actual total fertilizer N amounts needed by an irrigated chile crop usually equate to a total of 100 – 150 lbs. N/acre for the entire season. However, as previously stated, this rate can vary tremendously depending on actual crop and soil conditions.

Nitrogen management for irrigated chile should be directed to provide the total fertilizer N for a crop within the NAW with split applications toward a maximum target of approximately 100 – 150 lbs. N/acre. Late season N fertilizer applications can delay crop maturity and harvest. Crop and soil monitoring in-season is critical to allow appropriate adjustments in N fertilizer applications to best match in-season conditions in the field optimize this important facet of chile crop management.

Figure 1. Nitrogen (N) application window and maximum water demand period

for New Mexico type chiles in the desert Southwest of the U.S.

References

Baskerville, G.L. and P. Emin. 1969. Rapid estimation of heat accumulation from maximum and minimum temperatures. Ecology 50:514-517.

Brown, P. W. 1989. Heat units. Bull. 8915, Univ. of Arizona Cooperative Extension, College of Ag., Tucson, AZ.

Silvertooth, J.C. 2001. Feedback requirements for nitrogen in irrigated cotton. AZ1201, University of Arizona Cooperative Extension Bulletin.

Silvertooth, J.C., P.W. Brown, and S. Walker. 2010. Crop Growth and Development for Irrigated Chile (Capsicum annuum). AZ 1529, University of Arizona Cooperative Extension, College of Agriculture and Life Science, Tucson, AZ.

I hope you are frolicking in the fields of wildflowers picking the prettiest bugs.

I was scheduled to interview for plant pathologist position at Yuma on October 18, 2019. Few weeks before that date, I emailed Dr. Palumbo asking about the agriculture system in Yuma and what will be expected of me. He sent me every information that one can think of, which at the time I thought oh how nice!

When I started the position here and saw how much he does and how much busy he stays, I was eternally grateful of the time he took to provide me all the information, especially to someone he did not know at all.

Fast forward to first month at my job someone told me that the community wants me to be the Palumbo of Plant Pathology and I remember thinking what a big thing to ask..

He was my next-door mentor, and I would stop by with questions all the time especially after passing of my predecessor Dr. Matheron. Dr. Palumbo was always there to answer any question, gave me that little boost I needed, a little courage to write that email I needed to write, a rigid answer to stand my ground if needed. And not to mention the plant diagnosis. When the submitted samples did not look like a pathogen, taking samples to his office where he would look for insects with his little handheld lenses was one of my favorite times.

I also got to work with him in couple of projects, and he would tell me “call me John”. Uhh no, that was never going to happen.. until my last interaction with him, I would fluster when I talked to him, I would get nervous to have one of my idols listening to ME? Most times, I would forget what I was going to ask but at the same time be incredibly flabbergasted by the fact that I get to work next to this legend of a man, and get his opinions about pest management. Though I really did not like giving talks after him, as honestly, I would have nothing to offer after he has talked. Every time he waved at me in a meeting, I would blush and keep smiling for minutes, and I always knew I will forever be a fangirl..

Until we meet again.

At the 2023 Southwest Ag Summit Field Demo a couple of weeks ago, many of the latest technologies were demonstrated in the field. Most were related to pest control. Several of the technologies demonstrated or on display at the event are brand new to the Yuma, AZ area. The new technologies presented included an autonomous orchard sprayer (Fig. 1a), wide span (4 and 6 row) automated weeders (Fig. 1b, Fig. 1c), steam applicators for pre-plant weed control (Fig. 1d) and post-emergent weed control/crop desiccation (Fig. 1e) and a camera guided cultivator (Fig. 1f). This trend towards developing wider and more productive machine machines is indicative of a maturing industry. It will be interesting to watch these machines evolve further and become integrated in our cropping systems.

Fig. 1. New pest control technologies demonstrated/on display at the 2023 Southwest Ag Summit Field Demo included a) mini GUSS1 autonomous orchard sprayer, b) K.U.L.T.i - Select automated weeder, c) FarmWise’s Vulcan automated weeder, d) UC Davis/UofA band-steam applicator, e) X-Steam-inator’s steam applicator and f) Mantis Ag Technology’s camera-guided cultivator. (Photo credits Fig. 1d: Mazin Saber, University of Arizona)

____________________

[1] Reference to a product or company is for specific information only and does not endorse or recommend that product or company to the exclusion of others that may be suitable.

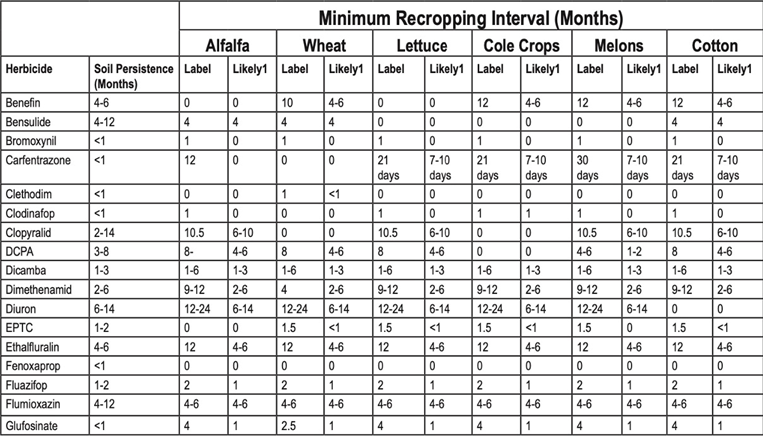

The IPM team has received questions about how to evaluate possible crop injury from herbicides that were applied in previous seasons. As we know residual soil activity is very useful when we needed but we must be very careful when the following crop is sensitive. Potential injury is affected by soil type, watering methods, weather, tillage, organic matter, or the combination of these factors.

The following is a chart that “Minimum Recroping Interval” contains the rotational crop interval and soil persistence of herbicides for the major crops and herbicides used in the desert. You can find this chart in the PCA Study Guide Section VI-26.

During 2014-2018 we ran an HPLC (High Pressure Liquid Chromatograph) in our Lab at the Ag. Center to quantify soil and plant herbicide residues free of charge. Currently we don’t have this equipment available so, we helped growers and PCAs evaluate potential herbicide injury using our greenhouses at the Yuma Ag Center (YAC). A basic bioassay can be done just by growing sensitive plants in pots containing soil from the field in question. Even though bioassays are often done with plants that are sensitive to the herbicide used, it is reasonable to use the crop and variety that will be planted.

Also, it is very important to collect small amounts (top 2-4 inches) from several areas of the field. Herbicide concentrations often changes within fields, so separate samples should be collected and labeled to indicate which block they come from.

We are also doing some field evaluations right now with bensulide and metolachlor in spinach at the UA YAC to answer some of your questions and results will be shared soon in this newsletter. If you have a suggestion or herbicide injury test or bioassay you want to run, please contact us at AZVegIPM-Team@email.arizona.edu.