There is a lot of discussion these days regarding the need for crop production systems in Arizona to improve upon the efficiencies of our irrigation systems. The focus on irrigation efficiencies has been accentuated with the current water shortages being experienced in many parts of the state and region, particularly with the Colorado River system.

Despite the focus on irrigation efficiency and the abundance of discussions and advice for the crop production community on how to go about the business of irrigating and producing a crop, very little, if any, comment is being made to define what is meant by “irrigation efficiency”.

There are several ways to define irrigation efficiency. The primary definitions for irrigation efficiency include orientations with water conveyance and delivery systems, agronomic, economic, and environmental efficiencies.

Water Conveyance and Delivery System Efficiency

In the desert Southwest we have the benefit of incredible engineering with the highly developed systems of dams, primary canals, pumps, laterals, and secondary canals that move water from rivers and groundwater supplies to areas of need, which are commonly managed by irrigation districts. Our ability to move water from the original source to the field is a critical aspect of managing water resources and there is an “efficiency” consideration in terms of how water is conveyed from the source to the field. This level of efficiency is largely a function of system engineering and design and the system management.

Agronomic Irrigation Efficiency

Agronomic (crop and soil) considerations are centered on our ability to provide irrigation water for the sustainable production of a crop in the field. The three primary demands for crop water management include: 1) providing water for seed germination and stand establishment, 2) providing irrigation water to match crop-consumptive water use, and 3) sufficient irrigation water to leach soluble salts from the root zone so that the soils can support crop production in a sustainable manner (Figure 1).

Agronomic efficiency at the field level focuses on the crop water demand (CWD) through crop consumptive use (ETc, which is the combination of evaporation and transpiration from the crop) and leaching requirements (LR, which are dependent upon the crop and salinity of the irrigation water).

Agronomic efficiency can be estimated by considering the difference between ETc + LR = CWD and the volume of irrigation water applied (IWA).

Leaching Requirement (LR) can be estimated by use of the following calculation:

Where:

ECw = salinity of the irrigation water, electrical conductivity (dS/m)

ECe = critical plant salinity tolerance, electrical conductivity (dS/m)

This is a good method of a LR calculation that has been utilized extensively and successfully in Arizona and the desert Southwest for many years. We can easily determine the salinity of our irrigation waters (ECw) and we can find the critical plant salinity tolerance level from easily available tabulations of salinity tolerance for many crops (Ayers and Westcot, 1989). Additional direct references are from Dr. E.V. Maas’ lab at the University of California (Maas, 1984: Maas, 1986; Maas and Grattan, 1999; Maas and Grieve, 1994; and Maas and Hoffman, 1997).

Economic Efficiency

Economic efficiency is often considered to be primary factor defining the financial sustainability of a farming operation. Water is a crop input and the costs associated with irrigating a crop includes the cost of the water directly and costs of delivery (pumps, equipment, maintenance, labor, etc.). Economic efficiency essentially considers the “return on the investment” and profitability of irrigating a crop.

Environmental Efficiency

Considerations of irrigation efficiency from an environmental perspective is very broad and encompassing and it can include a combination of efficiencies previously discussed (water conveyance systems, agronomic, and economic considerations). Environmental efficiency is a collective line of consideration regarding overall stewardship of water as a natural resource and beneficial use.

Estimating Field Level Irrigation Efficiencies

The focal point of any irrigation system, from the regional, district, farm, and field levels is to provide water to produce a crop. The crop is the centerpiece of the entire operation. Thus, I believe it is most appropriate to consider irrigation efficiency at the field level in agronomic terms, by use of Equation 1.

We need three factors to estimate field level irrigation efficiency for a crop: 1) crop evapotranspiration (ETc), 2) the crop and field leaching requirement (LR), and 3) a measure of the irrigation water applied to the field in question (IWA).

To determine crop evapotranspiration (ETc) we need a good reference evapotranspiration (ETo) measurement for the field site in question. Reference evapotranspiration (ETo) values multiplied by an appropriate crop coefficient (Kc) can provide very good estimates on actual crop evapotranspiration (ETc) rates as shown in the following equation:

The appropriate Kc values are specific for each crop species and stage of growth. We commonly use crop coefficient Kc values that are provided in the publication “Consumptive Use by Major Crops in the Desert Southwest” by Dr. Leonard Erie and his colleagues, USDA-ARS Conservation Research Report No. 29 and now most commonly from the publication FAO 56 “Crop Evapotranspiration-Guidelines for Computing Crop Water Requirements-FAO Irrigation and Drainage Paper 56” (Allen et al., 1998). Reference information for Kc values can be obtained in these publications for common crops grown in this region.

Example

If we consider an example lettuce crop irrigated with water that has ECw = 1.1 dS/m and the crop water demand (CWD) = 30 inches

Using Equations 1-3, an overall estimate of field level irrigation efficiency can be made. From Equation 2 we can estimate the leaching requirement.

ECw = 1.1 dS/m and ECe (lettuce) = 1.3 dS/m

LR = 1.1 dS/m / (5 X 1.3) – 1.1 = 1.1/5.4 = 0.20 = 20% leaching requirement

LR = 30 X 0.2 = 6.1 ~ 6 inches

Thus, CWD = 30 + 6 = 36 inches total

Assume: 40 inches of irrigation water was applied.

Agronomic efficiency (from Equation 1) = 36/40 = 0.9 = 90% efficiency

Note: If the LR were not included in the total CWD, efficiency would be: 30/40 = 75%

That is an important difference and distinction to understand and demonstrate.

The Arizona Meteorological Network (AZMET) system provides both historical and real-time weather information that can be used to track reference evapotranspiration (ETo) measured at a standardized and properly calibrated weather station site. Reference evapotranspiration values can be obtained daily from AZMET for the nearly 30 sites in Arizona, including the Yuma area and the lower Colorado River Valley. Very importantly, the AZMET is very high quality and the integrity of the system has been constantly managed for over 35 years, first under the direction of Dr. Paul Brown and now with Dr. Jeremy Weiss. This information can be valuable in crop water and irrigation management.

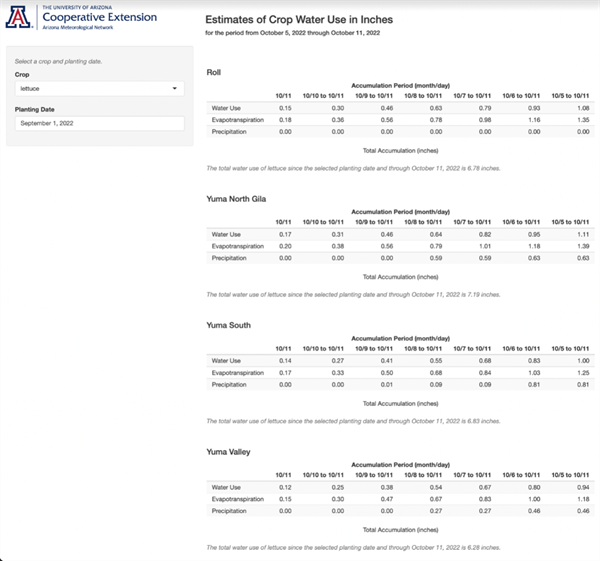

Dr. Jeremy Weiss, program manager for the University of Arizona AZMET system, has recently developed a valuable tool that provides actual crop evapotranspiration (ETc) estimates from several AZMET sites in the lower Colorado River Valley and for several key vegetable crops. Accumulations of ETc values over the previous week are shown based on a date of planting, which is selected by the user. In this model, the Kc values presented in FAO-56 are used for appropriate stages with each crop. The ETo measurements are taken directly from each AZMET site listed.

Dr. Weiss has included the next step with the development of this crop-water management tool that can provide the cumulative crop water use, cumulative ETc, during the growing season for a given crop and planting date for common leafy green vegetable crops in the lower Colorado River areas.

To access this crop-water estimate tool please refer to the following link:

https://viz.datascience.

For example, using lettuce (either iceberg or romaine) and 1 September planting date, we can see from this model that cumulative ETc from 10/5/22 to 10/11/22 is 1.11 inches in the North Gila Valley and 0.94 inches in the Yuma Valley (Figure 2). Cumulative ETc since the planting date is 7.19 and 6.28 inches for these two stations, respectively.

Dr. Weiss and I are working with this model in the field to evaluate and test it. I encourage farmers, agronomists, and field crop managers to review this information and check that against depletion rates of soil plant-available water in the field.

Figure 1. Soil-water balance and plant relationships in a crop production system.

Figure 2. Example of AZMET Crop Water Use estimates for lettuce planted on 1 September 2022 in the lower Colorado River Valley.

References

Allen, R. G., Pereira, L. S., Raes, D., & Smith, M. (1998). Crop evapotranspiration-Guidelines for computing crop water requirements-FAO Irrigation and drainage paper 56. FAO, Rome, 300(9), D05109.

Ayers, R.S. and D.W. Westcot. 1989 (reprinted 1994). Water quality for agriculture. FAO Irrigation and Drainage Paper 29 Rev. 1. ISBN 92-5-102263-1. Food and Agriculture Organization of the United Nations Rome, 1985 © FAO.

https://www.fao.org/3/t0234e/

Erie, L.J., O.A French, D.A. Bucks, and K. Harris. 1981. Consumptive Use of Water by Major Crops in the Southwestern United States. United States Department of Agriculture, Conservation Research Report No. 29.

Maas, E.V. 1984. Crop tolerance to salinity. California Agriculture, October 1984. https://calag.ucanr.edu/

Maas, E.V. 1986. Salt tolerance of plants. Appl. Agric. Res., 1, 12-36.

Maas, E.V. and S.R. Grattan. 1999. Crop yields as affected by salinity, Agricultural Drainage, Agronomy Monograph No. 38.

Maas, E. V., and Grattan, S. R. (1999). Crop yields as affected by salinity, agricultural

drainage, Agronomy Monograph No. 38, R. W.

Maas, E. V., and Grieve, C. M. 1994. “Salt tolerance of plants at different growth stages,” in Proc., Int. Conf. Current Developments in Salinity and Drought Tolerance of Plants. January 7–11, 1990, Tando Jam, Pakistan, 181–197.

Maas, E. V., and Hoffman, G. J. (1977). “Crop salt tolerance: Current assessment.”

This study was conducted at the Yuma Valley Agricultural Center. The soil was a silty clay loam (7-56-37 sand-silt-clay, pH 7.2, O.M. 0.7%). Spinach ‘Meerkat’ was seeded, then sprinkler-irrigated to germinate seed Jan 13, 2025 on beds with 84 in. between bed centers and containing 30 lines of seed per bed. All irrigation water was supplied by sprinkler irrigation. Treatments were replicated four times in a randomized complete block design. Replicate plots consisted of 15 ft lengths of bed separated by 3 ft lengths of nontreated bed. Treatments were applied with a CO2 backpack sprayer that delivered 50 gal/acre at 40 psi to flat-fan nozzles.

Downy mildew (caused by Peronospora farinosa f. sp. spinaciae)was first observed in plots on Mar 5 and final reading was taken on March 6 and March 7, 2025. Spray date for each treatments are listed in excel file with the results.

Disease severity was recorded by determining the percentage of infected leaves present within three 1-ft2areas within each of the four replicate plots per treatment. The number of spinach leaves in a 1-ft2area of bed was approximately 144. The percentage were then changed to 1-10scale, with 1 being 10% infection and 10 being 100% infection.

The data (found in the accompanying Excel file) illustrate the degree of disease reduction obtained by applications of the various tested fungicides. Products that provided most effective control against the disease include Orondis ultra, Zampro, Stargus, Cevya, Eject .Please see table for other treatments with significant disease suppression/control. No phytotoxicity was observed in any of the treatments in this trial.

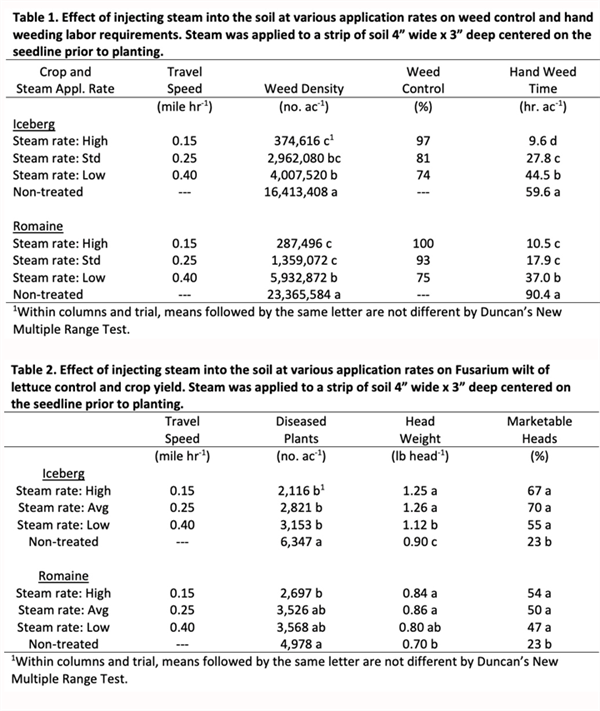

Last fall, we established trials investigating the use of band-steam to control weeds and Fusarium wilt of lettuce in iceberg and romaine lettuce. Band-steam is where, prior to planting, steam is injected in narrow bands, centered on the seedline to raise soil temperatures to levels sufficient to kill weed seed and soilborne pathogens (>140 °F for > 20 minutes). After the soil cools (<1 day), the crop is planted into the strips of disinfested soil.

In the study, we utilized the prototype band-steam applicator (Fig. 1) described in a previous UA Veg IPM articles (Vol. 11 (13) to inject steam into the soil as beds are shaped. The steam applicator was configured to treat a 4” wide by 3” deep band of soil. Three rates of steam (Low, Standard, High) were applied by varying travel speed. The “Standard” rate was where steam was applied at rates needed to reach the target soil temperatures (>140 °F for > 20 minutes). Higher and lower applications rate were examined to ensure target temperatures were met/exceeded to get a better understanding of the efficacy of steam treatment, and to determine if higher travel speeds (less fuel consumption) could be used and still provide effective pest control.

Results showed that application of steam was highly effective at controlling weeds (nettleleaf goosefoot predominant species). At the Standard application rate, over 80% of the weeds were controlled. At High application rates, weed control approached 100%. What was particularly encouraging was that at the Low steam application rate where travel speeds were 60% faster than Standard, and target temperatures were not met, weed control was still very good – about 75%.

Steam treatment was also effective at controlling Fusarium wilt of lettuce. Disease incidence in iceberg and romaine lettuce were reduced by more than 50% as compared to the untreated control (Table 2). Crop plants were noticeably larger and more vigorous throughout the growing season in all steam treated plots (Fig. 2). At the Standard and High application rates of steam, this translated into significant yield increases in iceberg (>300%) and romaine (>90%) lettuce. Significant yield increases were also found at the Low application rate of steam – iceberg (>200%) and romaine (>60%).

The results are very promising, but it is important to note that steam treatment is not an end-all cure for Fusarium wilt disease. At the trial site, disease inoculum levels were considered moderate. However, when inoculum levels are very high, our trials have shown that a 4” wide by 3” band of soil is not effective at controlling the disease. We hypothesize that a wider and/or deeper band of treated soil is needed for effective control. This fall, we will be initiating trials to examine this. We will also be investigating the use of band steam to control pythium and nematodes in carrot. Trial results will be presented in future articles - so Stay Tuned.

As always, if you are interested in seeing the machine operate or would like to test the machine on your farm, please feel free to contact me.

Acknowledgements

This work is supported by the Arizona Specialty Crop Block Grant Program and the Arizona Iceberg Lettuce Research Council. We greatly appreciate their support. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.

Fig. 1. Band-steam applicator principally comprising a 35 BHP steam generator mounted on a bed-shaper applicator sled.

Fig. 2. Iceberg lettuce planted in beds treated with steam (left) prior to planting and untreated (right).

Last Thursday April 28, 2022 the EPA issued a notice of intent to suspend (NOITS) DCPA, which when effective, will prevent the sale, distribution, and use of the technical-grade product containing the pesticide dimethyl tetrachloroterephthalate (DCPA).

Please see all details of the NOITS by clicking the following link:

https://www.epa.gov/pesticides/epa-issues-notice-intent-suspend-herbicide-dcpa

Dacthal was first registered in 1958[1] and we are constantly adjusting it to our changing cultural practices. Recently some evaluations were done of Dacthal’s safety to iceberg lettuce applied Pre and Post-Transplanting. The product showed promising results. It is a mitotic inhibitor and kills germinating weeds by stopping cell division. This mode of action is similar to preemergence herbicides such as Prowl, Kerb, Balan, Trifluralin and others but its chemistry and how it moves in the soil differs. Dacthal is absorbed by both shoots and roots of germinating seedlings although most of the activity is from shoot absorption. When absorbed by the shoots, it will move upward into the plant. It is not absorbed by foliage and can be safely applied over the crop. Dacthal adheres strongly to soil particles. The best time to apply Dacthal is when the soil is moist but not saturated[2].

We are also including in this update the statement from registrant AMVAC Corporation for more information regarding notice of intent to suspend DCPA: https://www.amvac.com/news/amvac-regulatory-issues-statement-regarding-dachtal-dcpa.

References: