Crop Consumptive Use and Measurement

While striving to continually improve efficiency in the management of our irrigation systems, it is important to understand basic crop water use patterns. Estimating and tracking actual crop-water use can be a valuable tool in understanding crop-water demand and irrigation management.

In desert crop production systems, water is the first limiting factor and irrigation is a primary driving force in the growth and development of the crop.

In the process of irrigating a field to support a crop, there are two primary objectives that we must address in a desert crop production system: 1) replenish the plant-available water in the soil profile and 2) provide sufficient irrigation water to accomplish the necessary leaching of soluble salts. In some cases, particularly with cool season plants, e.g. lettuce and cole crops, we sometimes irrigate to cool the soils for seed germination and stand establishment when seed placement is made in warm or hot soils.

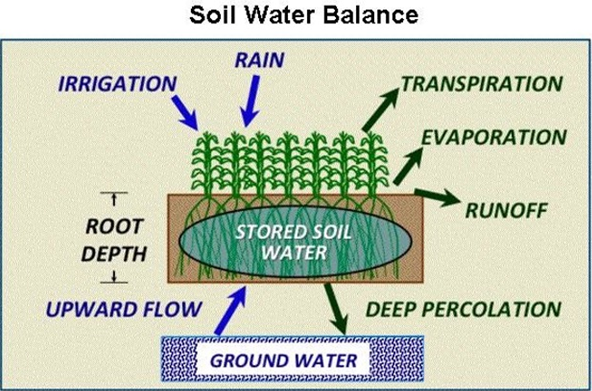

In a soil-plant system the dynamics of water-balance involves inputs (rainfall and/or irrigation) and several routes of possible water loss (Figure 1). The soil provides the water-holding capacity that offers water available for plant uptake through the root system. Ideally, we want all the irrigation water that we apply to be taken up by the crop for optimum plant health and water use efficiency.

Figure 1. Soil-water balance and plant relationships in a crop production system.

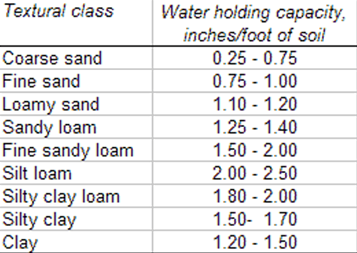

In managing irrigation events, we must take into consideration the amount of soil-water that has been depleted from the field by the crop since the last irrigation and we must also consider the water holding capacity of the soils in the field (Table 1). Deep percolation is often regarded as a loss of soil-water but in desert agriculture, but a sufficient degree of deep percolation is needed to remove soluble salts from the plant rootzone, e.g. leaching requirements.

Table 1. Soil texture and water holding capacity.

Comparing actual crop-water demand and crop irrigation practices can be important in our efforts to understand crop management needs and field-level irrigation efficiencies.

The collective loss of water from a field due to evaporation from the soil surface and transpiration of water vapor from the plants under standard conditions is referred to as “evapotranspiration, ET”.

Collectively, water used from the soil and plant system in a field is also referred to as “crop consumptive use”. It is important to understand this process to continually improve the management and stewardship of our water resources as we irrigate to replace water loss from the soil-plant system through the ET process, Figure 1.

The Arizona Meteorological Network (AZMET) system provides both historical and real-time weather information that can be used to track reference evapotranspiration (ETo) measured at a standardized and properly calibrated weather station site. This information can be valuable in crop water and irrigation management.

Reference evapotranspiration values can be obtained daily from AZMET for the nearly 30 sites in Arizona, including the Yuma area and the lower Colorado River Valley. Reference evapotranspiration (ETo) values multiplied by an appropriate crop coefficient (Kc) can provide very good estimates on actual crop evapotranspiration (ETc) rates as shown in the following equation:

ETc = ETo * Kc

The appropriate Kc values are specific for each crop species and stage of growth. We have commonly used crop coefficient Kc values that are provided in the publication “Consumptive Use by Major Crops in the Desert Southwest” by Dr. Leonard Erie and his colleagues, USDA-ARS Conservation Research Report No. 29. In recent years, we now use the Kc values found in the publication FAO 56 “Crop Evapotranspiration-Guidelines for Computing Crop Water Requirements-FAO Irrigation and Drainage Paper 56” (Allen et al., 1998). Reference information for Kc values can be obtained in these publications for common crops grown in this region.

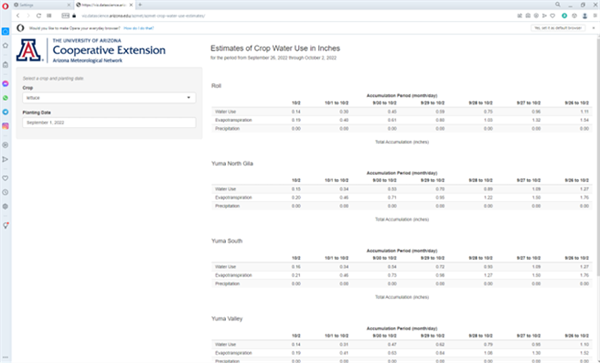

Dr. Jeremy Weiss, program manager for the University of Arizona AZMET system, has recently developed a valuable tool that provides actual crop evapotranspiration (ETc) estimates from several AZMET sites in the lower Colorado River Valley and for several key vegetable crops. Accumulations of ETc values over the previous week are shown based on a specific crop and date of planting, which are selected by the user. In this model, the Kc values presented in FAO-56 are used for appropriate stages with each crop. The ETo measurements are taken directly from each AZMET site listed.

To access this crop-water estimate tool please refer to the following link:

https://viz.datascience.arizona.edu/azmet/azmet-crop-water-use-estimates/

For example, using lettuce (either iceberg or romaine) and 1 September planting date, we can see from this model that accumulative ETc from 9/15/22 to 9/20/22 is 1.06 inches in the North Gila Valley and 0.90 in the Yuma Valley.

Figure 2. Example of AZMET Crop Water Use estimates on 3 October 2022 for lettuce planted on 1 September 2022 in the lower Colorado River Valley.

The next step with the development of this crop-water management tool will be to include cumulative crop water use, cumulative ETc, during the growing season for a given crop and planting date in the lower Colorado River areas.

Dr. Weiss and I are working with this model in the field to evaluate and test it. This crop water use tool can serve a valuable role in our continued efforts to improve irrigation and water management efficiencies. I encourage farmers, agronomists, and field crop managers to review this information and check that against depletion rates of soil plant-available water actually observed in the field.

We appreciate your review and any feedback and/or suggestions you may have.

References

Allen, R. G., Pereira, L. S., Raes, D., & Smith, M. (1998). Crop evapotranspiration-Guidelines for computing crop water requirements-FAO Irrigation and drainage paper 56. FAO, Rome, 300(9), D05109.

Erie, L.J., O.A French, D.A. Bucks, and K. Harris. 1981. Consumptive Use of Water by Major Crops in the Southwestern United States. United States Department of Agriculture, Conservation Research Report No. 29.

Frost and freeze damage affect countless fruit and vegetable growers leading to yield losses and occasionally the loss of the entire crop. Frost damage occurs when the temperature briefly dips below freezing (32°F).With a frost, the water within plant tissue may or may not actually freeze, depending on other conditions. A frost becomes a freeze event when ice forms within and between the cell walls of plant tissue. When this occurs, water expands and can burst cell walls. Symptoms of frost damage on vegetables include brown or blackening of plant tissues, dropping of leaves and flowers, translucent limp leaves, and cracking of the fruit. Symptoms are usually vegetable specific and vary depending on the hardiness of the crop and lowest temperature reached. A lot of times frost injury is followed by secondary infection by bacteria or opportunist fungi confusing with plant disease.

Most susceptible to frost and freezing injury: Asparagus, snap beans, Cucumbers, eggplant, lemons, lettuce, limes, okra, peppers, sweet potato

Moderately susceptible to frost and freezing injury: Broccoli, Carrots, Cauliflower, Celery, Grapefruit, Grapes, Oranges, Parsley, Radish, Spinach, Squash

Least susceptible to frost and freezing injury: Brussels sprouts, Cabbage, Dates, Kale, Kohlrabi, Parsnips, Turnips, Beets

More information:

As mentioned in a previous article, last month at the UC Cooperative Extension Automated Technology Field Day in Salinas, CA, several automated technologies were showcased operating in the field for the first time to a general audience. One of the “new” machines designed specifically for in-row weeding in vegetable crops was discussed previously, a second is highlighted here.

Vision Robotics1 (https://www.visionrobotics.com/) demoed an innovative mechanical in-row weeding machine (Fig. 1). As with most other automated weeding machines currently on the market, in-row weeds are controlled with knife blades that cycle in and out of the crop row. Each knife blade however is controlled independently by an electric motor rather than in coupled pairs. Another feature is that the imaging system calculates a prescribed path for the blades to follow based on a contour of the crop plant and a user defined offset distance from the contour (Fig. 2) Because electric motors are used, blade position can be continuously and precisely controlled, thus facilitating close cultivation.

In the demo, the prototype seemed to work pretty well, but the run was short, and it was difficult to fully evaluate its performance. The video they shared of their imaging system with path planning and blade movement operating in real time impressed and showed good promise (Fig. 2). The innovation was recently patented, and the company is planning commercial units for interested customers.

Developments such as these are worth investigating as our and other researchers’ studies have shown that automated in-row weeding machines control about 50-66% of the in-row weeds, and the majority of uncontrolled weeds were observed to be close to the crop plant (Lati et al., 2016; Mosqueda et al., 2021).

References

Lati, R.N, Siemens, M.C., Rachuy, J.S. & Fennimore, S.A. (2016). Intrarow Weed Removal in Broccoli and Transplanted Lettuce with an Intelligent Cultivator. Weed Technology, 30(3), 655-663.

Mosqueda, E., Smith, R. & Fennimore, S. 2021. 2020 Evaluations of automated weeders in lettuce production. ANR Blogs. Davis, Calif.: University of California Davis. Available at: https://ucanr.edu/blogs/blogcore/postdetail.cfm?postnum=45566.

Acknowledgements

A special thank you to Tony Koselka, Vision Robotics Inc., for uploading the videos referenced in this article.

____________________

[1] Reference to a product or company is for specific information only and does not endorse or recommend that product or company to the exclusion of others that may be suitable.

Fig. 1. Prototype in-row weeding machine developed by Vision Robotics1 demonstration at UCCE Automated Technologies Field Day. Clear here or on the image to view the machine in action.

Fig. 2. Plant contour and cultivating blade path planning of prototype in-row weeding machine developed by Vision Robotics1. A contour of the crop plant is traced (left) and a prescribed path a user defined distance from this contour (right) is determined for the blade tips to follow. Clear here or on the image to view the system in action.

As

we are all aware the most commonly used herbicides in lettuce production are

Kerb (Pronamide), Balan (Benefin), and Prefar (Bensulide). Our weed complex for

lettuce grown in the low desert includes summer annual weeds grasses and

broadleaves early in the season as well as winter annuals, which are a problem

during the cooler months. Most of these are controlled with preemergent

herbicides although escapes are common and must be controlled postemergence.

Occasionally when herbicides and cultural practices are not sufficient

expensive hand weeding is required for commercially acceptable weed control. To

illustrate numbers from our 2016 Crop losses report showed that 91% of the

lettuce surveyed required some hand hoeing even when 82% of the acres was

treated with Pronamide. Also Bensulide and Benefin were applied at lower

percent.

Therefore, evaluation of new effective herbicides is always welcomed. We

conducted a couple of projects at the Yuma Agricultural Center to look at weed

management in transplanted lettuce to determine Pre and Post-Transplant weed

control as well as crop safety of other active ingredients such as

S-metholachlor (Dual Magnum), Pendimethalin (Prowl), DCPA (Dacthal) and compare

them with Pronamide (Kerb) and other products.

Transplanting lettuce and the use of planting tape has opened the possibility

of using herbicides that injure direct seeded lettuce but may be safer to

plants with a developed root system. Additionally, they could show more

efficacy in controlling some weeds present in our area.

We are still collecting results from these trials and will publish them

soon in this Newsletter as well as in the upcoming Lettuce Crop Losses Workshop.

Prowl Applied Pre-transplant

Results of pheromone and sticky trap catches can be viewed here.

Corn earworm: CEW moth counts remain at low levels in all areas, well below average for this time of year.

Beet armyworm: Trap increased areawide; above average compared to previous years.

Cabbage looper: Cabbage looper counts decreased in all areas; below average for this time of season.

Diamondback moth: DBM moth counts decreased in most areas. About average for this time of the year.

Whitefly: Adult movement beginning at low levels, average for early spring.

Thrips: Thrips adult counts reached their peak for the season. Above average compared with previous years.

Aphids: Aphid movement decreased in all areas; below average for late-March.

Leafminers: Adults remain low in most locations, below average for March.