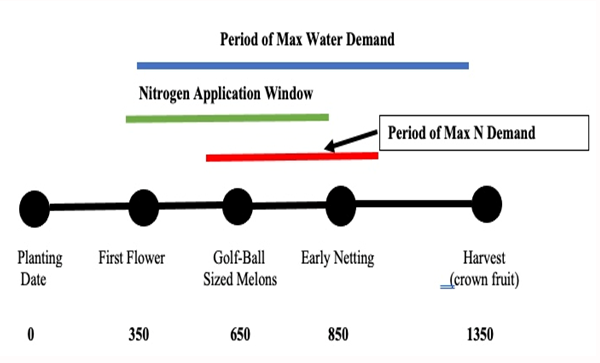

In a recent edition of this newsletter on 20 April 2022, I presented a cantaloupe phenological (crop growth and development) model based on heat units accumulated after planting (HUAP, 86/55 Fo thresholds) as shown in Figure 1.

The benefits of working with and using a model like this include being able to describe and predict important stages of crop growth and development (crop phenology) and harvest dates. This can also be a good tool for improving crop management (e.g., fertilization, irrigation, harvest scheduling, pest management activities, labor and machinery management, etc.).

Included in our work with the development of this phenological model, we have also conducted nutrient uptake studies and water use studies to develop a better understanding of nutrient and water demand for desert cantaloupe production (Silvertooth, 2003; Soto et al., 2006; and Soto, 2012).

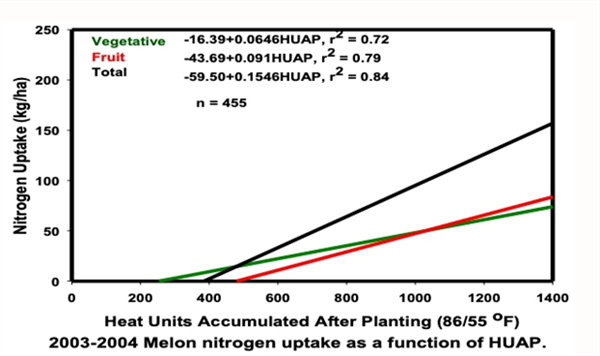

Figure 2 presents the nitrogen (N) uptake and portioning patterns for desert cantaloupes (melons), Silvertooth, 2003 and Soto et al. 2006. This data describes total N uptake for cantaloupes at ~ 140 lbs. N/acre. From this data, maximum N flux (N uptake/day) period extends from early fruit development to the netting stage.

Water use by desert cantaloupe production was also measured in these studies and patterns of water use followed the crop coefficient (Kc) patterns provided by the Arizona Meteorological Network (AZMET) and conformed to the Kc values from FAO 56 (Allen et al., 1998) and Grattan et al. (1998).

Considering N uptake and water demand patterns in relation to cantaloupe crop phenology, we can insert the overlaps as shown in Figure 1, with the red and blue lines for N and water management, respectively. Maximum N demand occurs from approximately 500 to 1,000 HUAP, which coincides with primary fruit development. Accordingly, the N application window for optimum N uptake is from approximately 300 to 800 HUAP, which is from early flowering to the netting stage of the crown fruit. The N application window is recommended in advance of the optimum N uptake period to provide for N mineralization and the plant-available forms of N for plant uptake and utilization.

Considering the N application window described in Figure 1 and a maximum seasonal uptake and demand of ~ 140 lbs. N/acre, early and split applications during this period of cantaloupe crop development can help achieve optimum utilization of fertilizer N inputs.

The period of maximum water demand extends from early fruiting stages of development through the maturation of the crown fruit, 300 to 1300 HUAP.

Considering the conditions we are experiencing these days in desert crop production with water shortages and extremely high prices of fertilizers, we have an abundance of motivation to manage our crop production systems with the highest efficiency possible. Understanding crop water and nutrient demand for each crop we are working with and using that knowledge to manage our crops most effectively, is to our benefit agronomically, economically, and environmentally.

Nitrogen is the plant nutrient required in largest amounts by most non-leguminous crops and it is important for us to manage that nutrient for a crop in a careful and deliberate manner. Water and N interactions are a critical aspect of crop growth, development, and management in any system, but particularly in an irrigated crop production system. Thus, the focus offered in this article on water and N management for desert cantaloupe production.

I encourage those who are working with spring cantaloupe production this season to test and evaluate this crop phenology model, particularly in relation to nutrient and water management under field conditions with various planting dates, varieties, and soil types. We appreciate your feedback.

Figure 1. Heat Units Accumulated After Planting (HUAP, 86/55 oF)

Figure 2. Cantaloupe (melon) N uptake and partitioning patterns. (Soto, Silvertooth, and Galadima 2006). Note: kg/ha * 0.89 = lbs/acre

References:

Grattan, S.R., W. Bowers, A. Dong, R.L. Snyder, J.J. Carroll, and W. George. 1998. New crop coefficients estimate water use of vegetables, row crops. California Agriculture 52(1):16-21.https://doi.org/10.3733/ca.v052n01p16

Allen, R.G., L.S. Pereira, D. Raes, and M. Smith. 1998. Crop evapotranspiration - Guidelines for computing crop water requirements - FAO Irrigation and drainage paper 56. Food and Agriculture Organization of the United Nations. Rome (FAO). https://www.fao.org/3/x0490e/x0490e0b.htm

Silvertooth, J.C. 2003. Nutrient uptake in irrigated cantaloupes. Annual meeting, ASA-CSSA-SSSA, Denver, CO.

Soto, R. O. 2012. Crop phenology and dry matter accumulation and portioning for irrigated spring cantaloupes in the desert Southwest. Ph.D. Dissertation, Department of Soil, Water and Environmental Science, University of Arizona.

Soto-Ortiz, R., J.C. Silvertooth, and A. Galadima. 2006. Nutrient uptake patterns in irrigated melons (Cucumis melo L.). Annual Meetings, ASA-CSSA-SSSA, Indianpolis, IN.

I am seeking samples of downy mildew on lettuce from around Yuma County to support the Michelmore Lab and their ongoing efforts to help characterize the downy mildew populations of the United States. The Michelmore Lab has led the charge on a survey of Bremia variants since 1980 and has been instrumental in demystifying the gene-for-gene nature of lettuce resistance to downy mildew.

Their group invites growers across the United States to submit downy mildew infected plant samples, which are then used to culture the Bremia on live host plants. The team then inoculates a panel of lettuce varieties carrying known resistance genes to determine the race of each isolate they receive. Identifying which races occur in which specific fields is essential to guiding the breeding of new resistant cultivars and maximizing the effectiveness of host-based genetic disease management. The data obtained from these tests are also used to designate new Bremia races through the International Bremia Evaluation Board.

Your contribution will help breed better lettuce for Yuma. This means less breakdown of resistance in the field, and better yields for Yuma growers. To facilitate these submissions the Yuma Plant Health Clinic will be setting up a separate drop-off point and submission sheet for downy mildew sample submissions in the same hallway we use for standard plant diagnostic submissions. The drop-off point will be clearly labelled and consist of a chest-style refrigerator and printed copies of the submission form. It is vital to keep these samples cool so they remain viable for future inoculations, so please place your samples inside of the refrigerator before you leave.

Shipping will be handled by the clinic. All we ask is that you fill out the submission form as completely as you can. An example of the questions that are asked in that form so you can prepare ahead of time can be found HERE .