Throughout the desert Southwest and across the nation, we have continued to experience high prices for fertilizers used in crop production agriculture. Accordingly, there are a lot of concerns and many anecdotes being passed around in an effort to understand the causes. Following a review of the current situation, the conditions that have created these high fertilizer prices, and the prospects for the future; there are many factors involved.

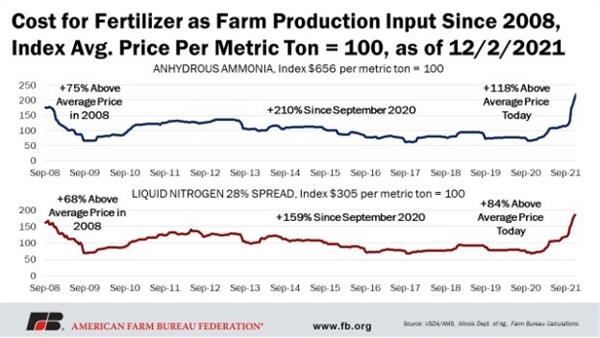

What we are experiencing is illustrated nicely in Figure 1, which describes the pattern of anhydrous ammonia (NH3) costs since September 2008. A very similar story is told in review of the costs for urea (46-0-0), diammonium phosphate (DAP, 18-46-0), and most other fertilizer materials. The high price trends we are now seeing began in September 2020.

Fertilizer prices also experienced a rapid increase in 2008 when nitrogen (N) fertilizer prices increased 32%, phosphate 93%, and potash 100%. Prices then dropped to pre-2007 levels by the end of 2009 and in review the surge was primarily due to high global and national demand and low inventories. The conditions we are now experiencing differ from the 2008 situation.

To better understand this current rise in fertilizer prices it is important to recognize that fertilizer is a global commodity and 44% of all fertilizer materials are exported to a different country. Thus, fertilizer production and prices are affected by other countries demanding fertilizer and the transportation rates to get the fertilizer to the final destination are all important factors.

The U.S. is the third-largest producer of fertilizers globally, and we require the importation of N, phosphorus (P), and potassium (K) to fully meet domestic demand. The U.S. fertilizer dealers and producers pay the price defined by the global market and that include the costs for the base fertilizer, other fertilizer materials, and the transportation requirements.

Anhydrous ammonia (NH3) provides a good example of the U.S. production in relation to the rest of the world. In 2020 NH3 was produced at 36 domestic plants and shipped around the country by pipeline, rail, barge, and truck. As of 2018, U.S. ranked second with 11.6% of global in NH3 production. China at 24.6% led in global NH3 production and India was ranked third with 11.3%.

For phosphate fertilizer production, the U.S. ranked 2nd with 9.9% of global production, led by China at 37.7%, and India with 9.8%.

For the mining and processing of potash (K2O) deposits, Canada is the global leader with 31.9% of global production, followed by Belarus with 16.5%, and Russia with 16.1%. The U.S. produces 0.8% of global potash and ranks 11th in the production of the global supply

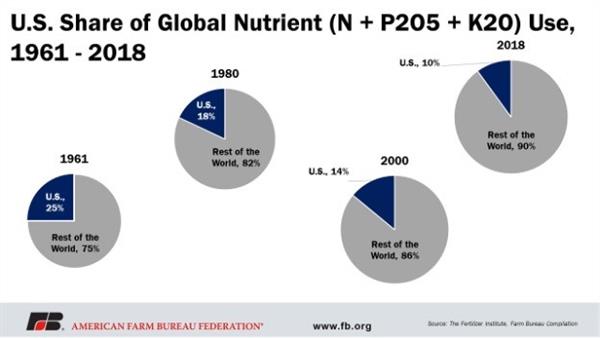

Thus, the U.S. is not the sole or dominant player in the global fertilizer industry or market. In point of fact, the U.S. share in terms of global use has dropped from 25% in 1961 to 10% in 2018.

Another major factor to consider are the energy requirements for the production and transport of fertilizer materials. Fertilizer production facilities require a large amount of energy to convert the raw chemical materials into their applicable farm-use state. This is very important in terms of N fertilizers.

There are two basic methods of fixing atmospheric diatomic N gas (N2), which is biologically inert and represents 78% of the earth’s atmosphere. The first, is the natural and miraculous process of biological N fixation which converts inert N2gas from the atmosphere into ammonium-N (NH4). The second is the industrial process, which is also amazing, where anhydrous ammonia is produced by the Haber-Bosch process and atmospheric N2 is combined with hydrogen (H) to synthesize the ammonia (NH3). This reaction is not thermodynamically favorable under natural conditions and huge amounts of energy with high temperatures and pressure are required to accomplish the process. In the Haber-Bosch process, natural gas is the H source and it also the energy source for further N fertilizer synthesis.

Energy costs account for 70% to 90% of the fertilizer production variable costs in the synthesis process. For example, 33 million metric British thermal units (MMBtu) per material ton of NH3 are required to make the conversion in the Haber-Bosch process. Natural gas prices have risen dramatically over the past year, especially in Europe where more than a 300% increase has been experienced since March 2021. This has forced many European Union N plants to close.

The aforementioned factors are dominating the increase in fertilizer prices that we are now experiencing. There are also other important factors including supply chain disruptions, trade duties, and geopolitics. These latter factors tend to get a lot of attention in the agricultural communities and the media often exacerbates that impression. But we see from this basic review, that there are many factors at play, and we can also better understand why fertilizer prices are not likely to come down soon.

Reference:

Myers, S. and N. Nigh. 2021. Too Many to Count: Factors Driving Fertilizer Prices Higher and Higher. Farm Bureau. https://www.fb.org/market-intel/too-many-to-count-factors-driving-fertilizer-prices-higher-and-higher

Figure 1. Pattern of anhydrous ammonia (NH3) costs since September 2008.

Figure 2. Pattern of U.S. share in the global nutrient market since 1961.

I hope you are frolicking in the fields of wildflowers picking the prettiest bugs.

I was scheduled to interview for plant pathologist position at Yuma on October 18, 2019. Few weeks before that date, I emailed Dr. Palumbo asking about the agriculture system in Yuma and what will be expected of me. He sent me every information that one can think of, which at the time I thought oh how nice!

When I started the position here and saw how much he does and how much busy he stays, I was eternally grateful of the time he took to provide me all the information, especially to someone he did not know at all.

Fast forward to first month at my job someone told me that the community wants me to be the Palumbo of Plant Pathology and I remember thinking what a big thing to ask..

He was my next-door mentor, and I would stop by with questions all the time especially after passing of my predecessor Dr. Matheron. Dr. Palumbo was always there to answer any question, gave me that little boost I needed, a little courage to write that email I needed to write, a rigid answer to stand my ground if needed. And not to mention the plant diagnosis. When the submitted samples did not look like a pathogen, taking samples to his office where he would look for insects with his little handheld lenses was one of my favorite times.

I also got to work with him in couple of projects, and he would tell me “call me John”. Uhh no, that was never going to happen.. until my last interaction with him, I would fluster when I talked to him, I would get nervous to have one of my idols listening to ME? Most times, I would forget what I was going to ask but at the same time be incredibly flabbergasted by the fact that I get to work next to this legend of a man, and get his opinions about pest management. Though I really did not like giving talks after him, as honestly, I would have nothing to offer after he has talked. Every time he waved at me in a meeting, I would blush and keep smiling for minutes, and I always knew I will forever be a fangirl..

Until we meet again.

Yesterday, we initiated our first trial of the season examining the use of band-steam for controlling Fusarium wilt of lettuce. The premise behind this research is to use steam heat to raise soil temperatures to levels sufficient to kill soilborne pathogens. For Fusarium oxysporum f. sp. lactucae, the pathogen which causes Fusarium wilt of lettuce, the required temperature for control is generally taken to be > 140°F for 20 minutes.

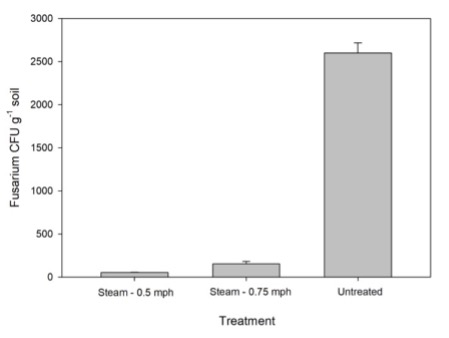

In our multi-year study, we are using a 35 BHP steam generator mounted on a custom designed elongated bed shaper to inject steam in the soil (Fig. 1). Trials conducted last fall show the technique holds promise. Fusarium colony forming units (CFU) were reduced from 2,600 in the control to 155 in the 0.75 mph travel speed and 53 in the 0.5 mph travel speed treatments, respectively (Fig. 2).

Fusarium load at the site where this week’s trial was conducted is reportedly high and we’re looking forward to obtaining good results. We’re also planning a second trial later this month at the Yuma Ag Center that is also focused on Fusarium wilt of lettuce control.

Stay tuned for results of all our trials examining the efficacy of using steam heat to control Fusarium wilt of lettuce, sclerotinia lettuce drop, pythium and weeds.

As always, if you are interested in seeing the machine operate or would like more information, please contact me.

Acknowledgements

This project is sponsored by USDA-NIFA and the Arizona Specialty Crop Block Grant Program. We greatly appreciate their support. A special thank you is extended to Larry Ott and Gila Valley Farms for allowing us to conduct this research on their farm. Fig. 1. Prototype band-steam applicator/bed shaper operating in Wellton, AZ. Fig. 2. Effect of band-steam applied at two travel speeds on Fusarium colony forming units (CFU) in the soil.

Fig. 1. Prototype band-steam applicator/bed shaper operating in Wellton, AZ.

Fig. 2. Effect of band-steam applied at two travel speeds on Fusarium colony

forming units (CFU) in the soil.

It is much easier to kill weeds when there is no crop in the field and now is a good time to reduce the seed bank of summer annual weeds in fallow fields. Weed seeds are buried at variable depths in the soil, some have hard seed coats and there are other variables that cause them to germinate over a long period of time. If they all came up at the same time they would be much easier to control. It takes time, therefore, to repeatedly irrigate, germinate and kill weeds with either tillage or herbicides. We have conducted trials that indicate that in most years summer annual weeds begin to germinate in February, reach a peak in June but continue to germinate into October.

Proper timing of tillage to kill weeds can be important with some species. Some weeds like common Purslane are very succulent and can remain viable for several days after cultivation or hoeing. They can reroot at the nodes and continue to grow if they are allowed to get too big before they are uprooted. Growers sometimes allow early emerging weeds to get fairly big in an effort to germinate as many seeds as possible. Incorporating large amounts of organic matter into the soil can also have a negative effect on some preemergent herbicides used in vegetables. Many of the root and shoot inhibitor herbicides like Trifluaralin, Pendimethalin, Benefin, DCPA and others can bind to organic matter and be less available to kill weeds.

Tillage has the opposite effect on perennial weeds such as nutsedge and bermudagrass than it has on annual weeds. These weeds are spread vegetatively and repeatedly irrigating and tilling them will spread rather than kill them.

Both contact and systemic herbicides are used during fallow periods to control weeds. The contact herbicides include Paraquat (Gramoxone, Firestorm), Carfentrazone (Aim, Shark), Pyraflufen (ET), Pelegonic Acid (Scythe),Glufosinate (Rely,Liberty) and others. Some of the advantages of these are that they are quick and have no soil residual allowing crops to be planted soon after application. Disadvantages are that they are effective primarily only on small weeds.

The most commonly used systemic herbicide for fallow ground is Glyphosate. It is broad spectrum and has no soil residual. Many of the systemic herbicides registered for fallow use, such as Oxyfluorfen (Goal, Galigan) or EPTC (Eptam) require at least 90 days before planting many vegetable crops. If done correctly, Eptam can be very effective in controlling nutsedge during summer fallow.

Only the fumigants kill weed seeds. These include Chloropicrin, Methyl Bromide, Metam Sodium, Dazomet, Telone and others. Most preemergent herbicides only work after the seed has germinated. Preemergent herbicides are often used for fallow weed control only when at least 30 to 45 days or longer are available. Fumigants are expensive, can be difficult to use and are often used for disease or nematode control with the added benefit of controlling weeds. Unlike soil active herbicides, Fumigants do not have any residual activity.

Soil solarization and flooding have become increasingly popular in recent years as techniques to control pests during summer fallow. Few regions are as well suited for these techniques as the low desert. They are used primarily to control diseases but have the benefit of controlling some summer annual weeds as well. Summer flooding works better here in the low desert than it does in many places because of the high temperatures and high respiration demands. The availability of oxygen is cut off to the roots when it is most needed. It is necessary to keep the field continuously flooded at a depth of 6 to 8 inches for 3 to 8 weeks. Some species are much more sensitive than others to this technique. Perennial weeds are more sensitive than are many annual weeds. Pigweed, field bindweed and nutsedge survive while many annual grasses do not.