In Arizona we tend to focus on the leafy green vegetable produce industry when addressing Arizona vegetable crop production. That is quite understandable given the size, scope, and impact of the leafy green vegetable industry based in the lower Colorado River Valley in the Yuma region.

As the leafy green vegetable industry is getting started and building in the early months of the fall, chiles, another important Arizona vegetable crop and one of my favorites, is maturing and advancing in the later stages of the production season in the higher elevation valleys of southeastern Arizona, primarily Cochise County.

We commonly refer to the Southwestern (SW) Chile Belt extending from southeast Arizona, across southern New Mexico, into far-west Texas, and northern Chihuahua, Mexico. The SW Chile Belt is dominated by production the New Mexico-type chile, also commonly referred to as “Hatch chile”. The 2021 acreage across the SW Chile Belt consists of approximately 7-8,000 acres in NM, 3-4,000 in TX, approximately 90,000 acres in Chihuahua, and about 300-500 acres in Arizona. The Curry Chile Seed Company, based in Pearce, AZ, provides the seed for >90% of the total green chile acreage across the SW Chile Belt.

Chile peppers (Capsicum species) are among the first crops domesticated in the Western Hemisphere about 10,000 BCE (Perry et al., 2007). The Capsicum genus became important to people and as result, five different Capsicum species were independently domesticated in various regions of the Americas (Bosland &Votava, 2012). Early domestication of chile peppers by indigenous peoples was commonly driven for use as medicinal plants. Due to their flavor and heat characteristics, chile peppers are a food ingredient that is popular in many parts of the world, including Latin American, African, and Asian cuisines. Chiles have been increasingly important to the U.S. and European food industries, particularly as these populations become more familiar with chile (Guzman and Bosland, 2017).

There are five domesticated species of chile peppers. 1) Capsicum annuum is probably the most common to us and it includes many common varieties such as bell peppers, wax, cayenne, jalapeños, Thai peppers, chiltepin, and all forms of New Mexico chile. 2) Capsicum frutescens includes malagueta, tabasco, piri piri, and Malawian Kambuzi. 3)Capsicum chinense includes what many consider the hottest peppers such as the naga, habanero, Datil, and Scotch bonnet. 4) Capsicum pubescens includes the South American rocoto peppers. 5) Capsicum baccatum includes the South American aji peppers.

The Capsicum annuum species is the most common group of chiles that we encounter and there are at least 14 very different pod types in this single species that includes: New Mexico (aka Anaheim), bell peppers, cayennes, jalapeños, paprika, serrano, pequin, pimiento, yellow wax, tomato, cherry, cascabel, ancho (mulato, pasilla), and guajillo (Guzman and Bosland, 2017).

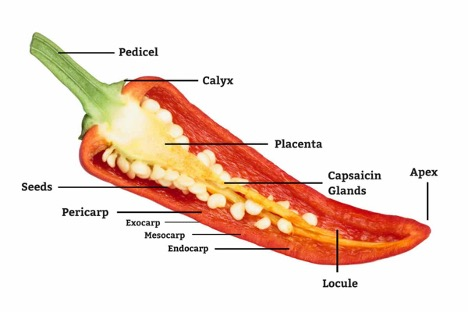

The source of heat in a chile comes from the capsaicin glands that run down the length of the placenta of the chile fruit. If we look at a longitudinal cross section of a chile pod (Figure 1), we can identify the placenta, the seeds, and the location of the capsaicin glands. The seeds are commonly mistaken as the source of the heat in a chile pod. This is due to the close proximity of the seeds to the placenta and capsaicin glands. The extent of the capsaicin glands is a function of genetics and in the field we know the classification of mild, medium, or hot varieties. Unfortunately, many commercial vendors do not segregate by variety and they just dump them all together, so we end up getting a rather random selection in the store.

The intensity of the "heat" of chile peppers is commonly reported in Scoville heat units (SHU). Originally, it was a measure of the dilution of an amount of chile extract added to sugar syrup before its heat is undetectable to a panel of tasters, or the more it has to be diluted to be undetectable. Thus, the more powerful the variety, the higher the rating. The modern method of determining capsaicin content is by use of a quantitative analysis of SHU using high-performance liquid chromatography (HPLC) to directly measure the total capsaicinoid content of a chile pepper sample. Pure capsaicin is a hydrophobic, colorless, odorless, and crystalline-to-waxy solid at room temperature, and measures 16,000,000 SHU (Guzman and Bosland, 2017).

Most of the commercial green chiles go into canning and food product development, e.g. salsas, etc. The varieties grown for red chile types are produced primarily for the dry chile powder. Red chiles represent the largest section of the SW and global chile industry.

References:

Bosland, P.W., E.J. Votava, and E.M. Votava. 2012. Peppers: Vegetable and spice capsicums. Wallingford, U.K.: CAB Intl.

Guzmán, I. and P.W. Bosland. Sensory properties of chile pepper heat - and its importance to food quality and cultural preference. Appetite, 2017 Oct 1;117:186-190.

doi: 10.1016/j.appet.2017.06.026.

Perry, L., Dickau, R., Zarrillo, S., Holst, I., Pearsall, D. M., Piperno, D. R., et al. (2007). Starch fossils and the domestication and dispersal of chili peppers (Capsicum spp. L.) in the Americas. Science, 315, 986-988.

Figure 1. Chile pod anatomy.

I hope you are frolicking in the fields of wildflowers picking the prettiest bugs.

I was scheduled to interview for plant pathologist position at Yuma on October 18, 2019. Few weeks before that date, I emailed Dr. Palumbo asking about the agriculture system in Yuma and what will be expected of me. He sent me every information that one can think of, which at the time I thought oh how nice!

When I started the position here and saw how much he does and how much busy he stays, I was eternally grateful of the time he took to provide me all the information, especially to someone he did not know at all.

Fast forward to first month at my job someone told me that the community wants me to be the Palumbo of Plant Pathology and I remember thinking what a big thing to ask..

He was my next-door mentor, and I would stop by with questions all the time especially after passing of my predecessor Dr. Matheron. Dr. Palumbo was always there to answer any question, gave me that little boost I needed, a little courage to write that email I needed to write, a rigid answer to stand my ground if needed. And not to mention the plant diagnosis. When the submitted samples did not look like a pathogen, taking samples to his office where he would look for insects with his little handheld lenses was one of my favorite times.

I also got to work with him in couple of projects, and he would tell me “call me John”. Uhh no, that was never going to happen.. until my last interaction with him, I would fluster when I talked to him, I would get nervous to have one of my idols listening to ME? Most times, I would forget what I was going to ask but at the same time be incredibly flabbergasted by the fact that I get to work next to this legend of a man, and get his opinions about pest management. Though I really did not like giving talks after him, as honestly, I would have nothing to offer after he has talked. Every time he waved at me in a meeting, I would blush and keep smiling for minutes, and I always knew I will forever be a fangirl..

Until we meet again.

Today's video is a demonstration of a spray assembly delivering herbicidal spray (blue dye) to spot spray targeted weeds. This devise can be integrated with an imaging system for precision, automated / robotic weed control.

CHECK IT OUT!

Herbicide resistant weeds have received a lot of attention in recent years. It is often misunderstood. Three of the most misunderstood concepts regarding herbicide resistance are: 1- Weed tolerance and weed selection are not resistance,2- Weed resistance is not universal and does not affect every weed of a certain species from field to field or within a field and weed resistance often takes much longer than insect resistance that is more common and occurs faster.

No Herbicide controls all weeds. Those weeds that are not controlled are tolerant. They never were controlled by that particular herbicide and they are often selected for and become more prevalent over time if the same herbicide is used. Resistant weeds, on the other hand, were controlled at one time by a particular herbicide and have naturally developed a trait that stops the herbicide from working. These resistant weeds survive from generation to generation and become more prevalent over time.

Weed resistance does not occur in all weeds in a field at the same time. It can be just one plant of trillions in a field. As this plant survives the herbicide and goes to seed it becomes more widespread in the field and in other fields. We conducted a trial in Parker last year where sprangletop survived Glyphosate in one field and was killed by the same treatment down the road. If your neighbor has resistant weeds it doesn’t mean that you do too.

Lastly, insect resistance to insecticides has occurred in this region for many years and was the first exposure that many pest control advisers and growers had to pesticide resistance. The principals are the same although insects generally produce multiple generations per season and mutations that facilitate resistance occur faster than for weeds. Annual weeds often produce only one or two generations per season and resistance takes much longer.