Whenever we go to the field to evaluate a crop, there are typically three fundamental points we need to take into consideration that include: 1) stage of growth, 2) general crop vigor and condition, and 3) anticipate the next stage of development and what we need to do in managerial response. These considerations are commonly focused on aboveground crop evaluations. However, the root system, completely belowground, is an extremely important part of the crop condition to evaluate.

Root systems are responsible for all water and nutrient uptake by the plant and provides the physical anchoring and support of the plant structure. Each plant and crop species has its own “personality” and growth habits and the nature of the root systems also vary among plants species. Many plant species can have root systems that constitute ~ 50% of the total plant dry matter and we generally consider plants to have at least 30% of total plant dry matter allocated to the root systems.

Young plants will often develop some basic aboveground tissue to perform sufficient photosynthesis for establishment and then devote a high amount of the energy, carbohydrates produced, along with the nutrients and water from the soil to root system growth and development. Sometimes it can appear that plants are not growing rapidly while investing energy and resources into root system development. The depth of the roots will vary according to the soil physical conditions and effective soil depth, soil fertility and salinity management, plant-available water, and of course the natural rooting characteristics of the plant.

The effective root zone depth is the depth of soil used by the bulk of the plant root system to explore a soil volume and obtain plant-available moisture and plant nutrients. Effective root depth is not the same as the maximum root zone depth. As a rule of thumb, we commonly consider about 70% of the moisture that is taken up by the root is obtained in the top half of the root zone; about 20% from the third quarter; and about 10% from the soil in the deepest quarter of the root zone. The small and very fine root hairs are the most physiologically active portion of a developing root system. It is important that the plants continue to develop and generate fresh young roots and an abundance of fine root hairs to maintain water and nutrient uptake.

Therefore, in scouting fields and making crop evaluations, examining the root systems is an important part of the process. Leafy green vegetable crops need to develop a marketable plant in a relatively short amount of time and a strong root system is essential. It does take more time and effort to check root systems and it is a plant destructive process since we need to literally excavate the roots. So, it is also important be careful of where and how we sample plants and the root systems in a field.

I hope you are frolicking in the fields of wildflowers picking the prettiest bugs.

I was scheduled to interview for plant pathologist position at Yuma on October 18, 2019. Few weeks before that date, I emailed Dr. Palumbo asking about the agriculture system in Yuma and what will be expected of me. He sent me every information that one can think of, which at the time I thought oh how nice!

When I started the position here and saw how much he does and how much busy he stays, I was eternally grateful of the time he took to provide me all the information, especially to someone he did not know at all.

Fast forward to first month at my job someone told me that the community wants me to be the Palumbo of Plant Pathology and I remember thinking what a big thing to ask..

He was my next-door mentor, and I would stop by with questions all the time especially after passing of my predecessor Dr. Matheron. Dr. Palumbo was always there to answer any question, gave me that little boost I needed, a little courage to write that email I needed to write, a rigid answer to stand my ground if needed. And not to mention the plant diagnosis. When the submitted samples did not look like a pathogen, taking samples to his office where he would look for insects with his little handheld lenses was one of my favorite times.

I also got to work with him in couple of projects, and he would tell me “call me John”. Uhh no, that was never going to happen.. until my last interaction with him, I would fluster when I talked to him, I would get nervous to have one of my idols listening to ME? Most times, I would forget what I was going to ask but at the same time be incredibly flabbergasted by the fact that I get to work next to this legend of a man, and get his opinions about pest management. Though I really did not like giving talks after him, as honestly, I would have nothing to offer after he has talked. Every time he waved at me in a meeting, I would blush and keep smiling for minutes, and I always knew I will forever be a fangirl..

Until we meet again.

Mark C. Siemens

Vol. 12, Issue 9, Published 5/5/2021

Automated thinning machines have been commercially available since 2012. These machines identify crop plants and intermittently deliver an herbicidal spray or dose of liquid fertilizer to thin the stand to the desired plant spacing. Some growers have converted older machines to spot apply pesticides to crop plants rather than thin lettuce. Spot spraying just the crop plant makes sense – it reduces applied chemical amount by about 1/3rd as compared to band spraying and by roughly 90% as compared to broadcast. I have heard reports of improved efficacy with this technique, perhaps due to better coverage, however this potential benefit has not been validated in formal trials.

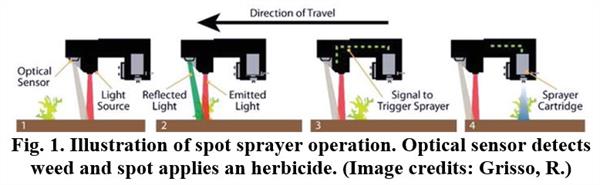

A drawback with automated thinning machines is their high cost. Retail prices for machines are approximately $25,000 per seed line, or about $200,000 for a 4-row, 2-line machine. Another option might be to use automated systems designed for spot spraying weeds. These devices have been commercially available since the mid 90’s and function similarly to automated thinning machines in that they use optical sensors to detect plants and solenoid activated spray assemblies to intermittingly spray unwanted plants (Fig. 1). The cost of these devices is quite reasonable – about $3,000 per unit, or about $24,000 for a 4-row, 2-line machine.

Automated spot sprayers are typically used in agriculture to control weeds in fallow fields (Fig. 2), but could easily be adapted to apply pesticides or even fertilizer to vegetable crops. Spot applying foliar fertilizers to vegetable crops is an interesting concept and is being investigated in California with lettuce.

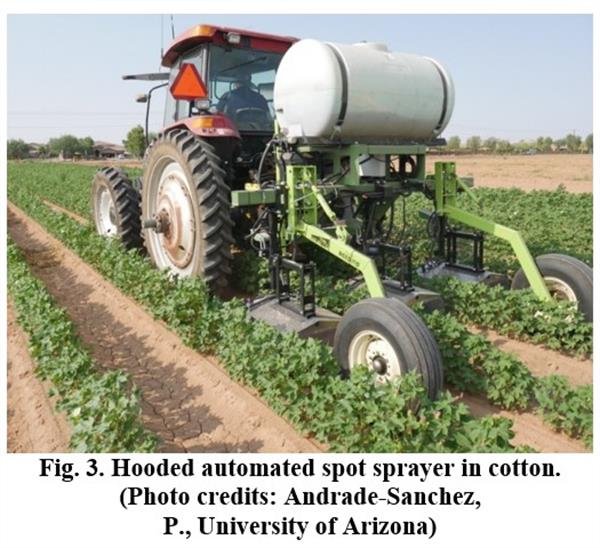

Another potential use of spot sprayers is to control herbicide resistant weeds. The device can be positioned between crop rows to spot spray a non-selective herbicide to target weeds. Placing the sprayer in a hooded enclosure prevents unwanted drift onto crop plants. We are conducting trials using this technique in cotton this season (Fig. 3). We are also looking for collaborators interested in trying the device as a pesticide and/or fertilizer spot applicator in vegetable crops for this upcoming season. If you are interested collaborating or would like to see a demo of the device, please feel free to reach out to me.

Oxyfluorfen,(Goal and Galigan) has become a popular and effective herbicide for use on cole crops even though it was first registered in the 1980’s. Oxyfluorfen is a contact herbicide with the same mode of action as Chateau, Aim, Shark, Gramoxone, Paraquat , Sharpen and ET. They are all PPO Inhibitors that rupture cell membranes. Carfentrazone (Aim, Shark), ET and Paraquat (Gramoxone), are effective only as postemergence applications to small weeds, Sharpen and Goal are effective both preemergence and early postemergence and Chateau is used only preemergence but can cause severe crop injury if mixed with a surfactant. The only one of these that is registered for cole crops is Oxyfluorfen (Goal, GoalTender, Galigan). It does not make sense for a contact herbicide to be used on weeds that have not emerged. The way this works is that a barrier is created with the herbicide on the surface that kills the seedling weeds as they come in contact with it. It is important not to disturb this barrier or the weeds will not be affected. Oxyfluorfen (Goal) is an herbicide that defies reason in other ways as well. It normally adheres strongly to the soil and has very low water solubility. It is well known, however, that Goal can lift off of the surface and cause crop injury. When this happens, it is evaporating or going from a liquid to a gas and this is unaffected by its solubility or adsorption. It also works well when chemigated through a sprinkler system. You would think that it would wash off, but it works well with less crop injury when chemigated. Chemigation is registered for onions only but it works well with cole crops as well. It only takes half as much (4 ounces) and is safer to the crop when chemigated. It is best to apply it about 2/3 of the way through the sprinkler run to keep it in place and flush the system.