It’s September and planting season is underway. When planting lettuce, uniform seed spacing is critical for efficient, economical crop thinning. Seedlings spaced too close together, commonly referred to as “doubles”, are difficult and time consuming to remove by hand. Automated thinning machines which intermittently deliver an herbicidal solution to thin excessive plants often consider doubles as a single plant. In such instances, both seedlings are left in the field (Fig. 1). This results in increased labor costs during the subsequent hand weeding operation where weeds and doubles are removed.

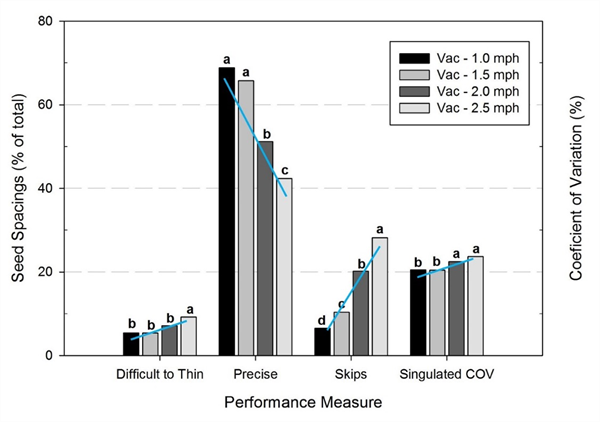

Several years ago, we conducted trials examining the influence of planter travel speed on seed spacing uniformity (Siemens and Gayler, 2016). In the study, a Stanhay 785 Singulaire vacuum planter was tested at travel speeds of 1.0, 1.5, 2.0 and 2.5 mph on shaped beds at the Yuma Agricultural Center. The results showed that the percentage of “difficult to thin” spacings, defined as doubles and seeds spaced less than 1 1/8” apart, increased from about 5% to 10% as speed increased from 1.0 mph to 2.5 mph (Fig. 2) . Similarly, the percentage of seeds “precisely placed” within 0.5” of the target location (i.e., 2.0 ± 0.5”) decreased from 70% to less than 45%, and the percentage of skips increased from 7% to 30%. Variability of seed spacing uniformity as measured by the coefficient of variation (COV) of seed spacings also increased. In short, planter travel speed had a significant effect on seed spacing uniformity and doubles - the higher the speed, the poorer the performance.

You may be asking what is the reason for the phenomenon observed? A logical explanation is that seeds are traveling at the speed of the planter when they are released and tend to “bounce and roll” in the direction of travel when they hit the soil surface. Thus, the higher the travel speed, the further seeds bounce and roll resulting in increased seed spacing variability. Other factors such as bed condition (i.e., cloddy vs well tilled) can also affect the amount of bounce and roll and cause poor seed placement and closely spaced seedlings that are difficult to thin (Fig. 3).

If you would like more information on how to accurately assess and analyze planter performance or are interested in conducting trials to determine how planter speed is affecting the percentage of doubles in your field conditions, please feel free to contact me.

References

Siemens, M.C., & Gayler, R.R. (2016). Improving seed spacing uniformity of precision vegetable planters. Appl. Eng. Agric., 32(5), 579-587.

Fig. 1. Lettuce seedlings intermittingly sprayed with an herbicidal solution by

automated thinning machine for purpose of thinning excess seedlings. Examples

of closely spaced seedlings, “doubles”, that are not sprayed and must be

subsequently thinned by hand (circled).

Fig. 2. Seeding performance of a vegetable planter sowing lettuce when

operated at four travel speeds.

Fig. 3. Poor seed spacing uniformity, possibly due to cloddy soil

conditions causing excessive seed bounce and roll.